SPM'S

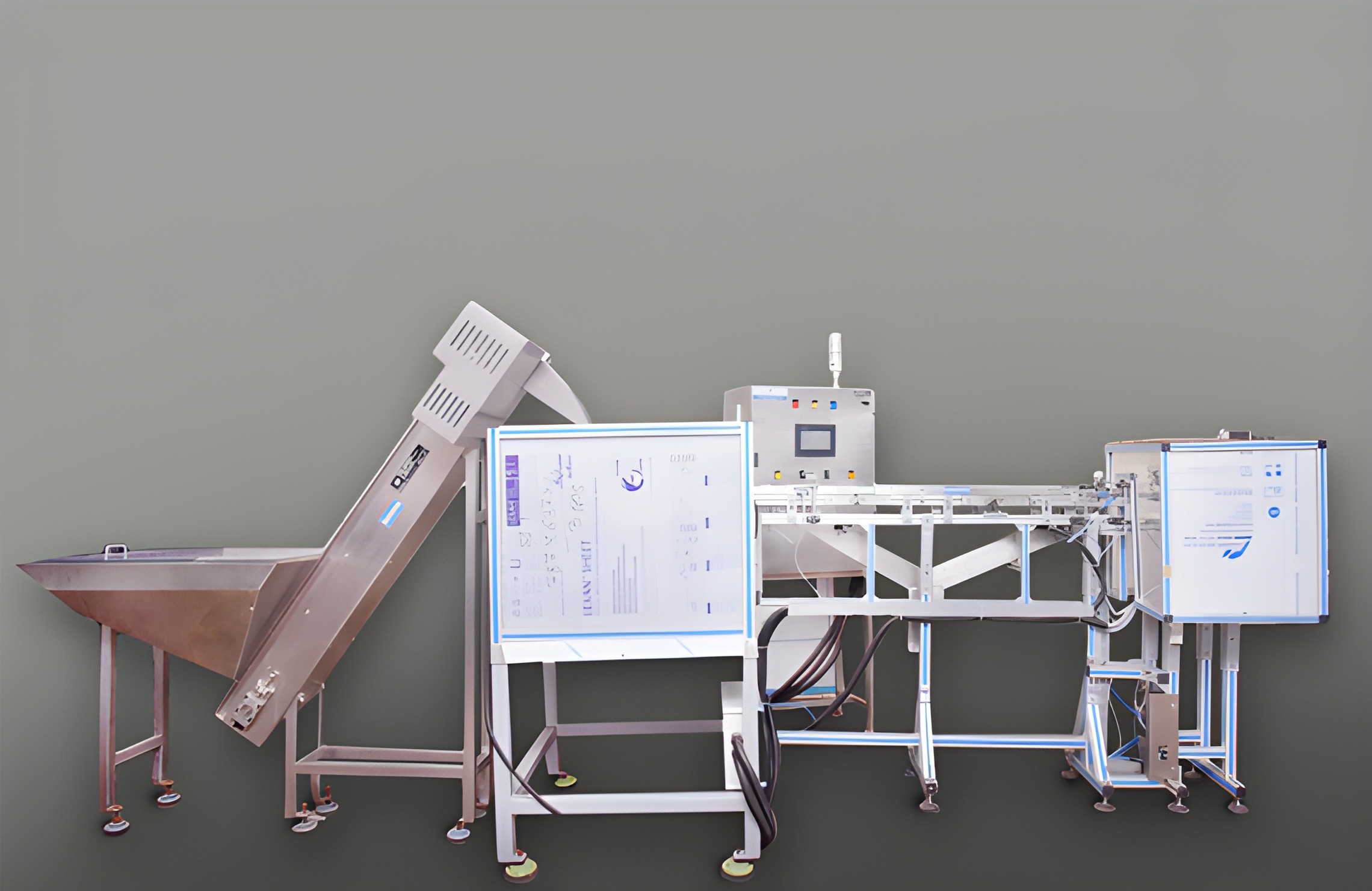

Buffing Automation

Buffing automation is specially designed for polishing electrical switch with full automation and can be use for all types of switches with minor change over & setting.

- Auto loading and unloading of components.

- High speed buffing.

- Buffing wheel height Adjustment.

- Safety canopy Enclosure.

- 60 Switch Per min buffing.

- Manless Operation.

- Safety starts push button.

- Easy Maintenance for all parts.

- PLC Base Control Panel.

- Automatic detect faulty and broken switch.

- High Speed Auto Loading By Bowl Feeder.

- Buffing Wheel for polish.

- Speed Control Adjustment.

- PLC Control Panel.

- Powerful Induction Motor.

- Loading switch detection Sensor.

- Start, Stop & Emergency Switches.

- Automatic Pneumatic Operation.

- Suited for all type of Switch.

- Buffing for all components for glossy finish.

AUTOMATION CONDITION’S

- Unskilled welding operator can operate.

- Time require for loading-unloading is less.

- Reajection rate down to almost 0%.

- No cost of inventy increase due to machine.

- Low operator cost.

- Due safety canopy and safety sensors no possibility of accidents and injuries .

- Increase in production rate by 50%.

- No overdue expenses except minimal cost of maintainance

MANUAL CONDITION’S

- Skilled welding operator requires.

- Excess time require for arrangments.

- Rejection rate upto 20% due to quality of spots and welding.

- Cost of inventy increase.

- Operating cost increases per year.

- Possibility of accidents and operator safety cost per year.

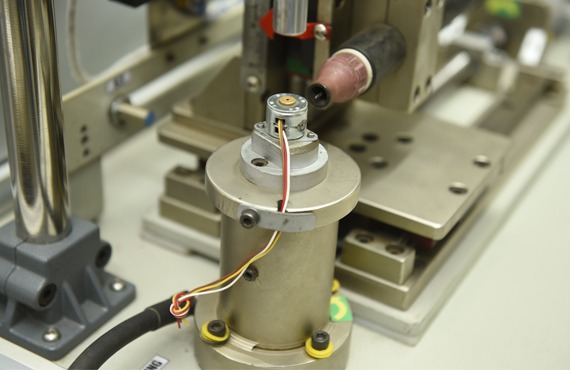

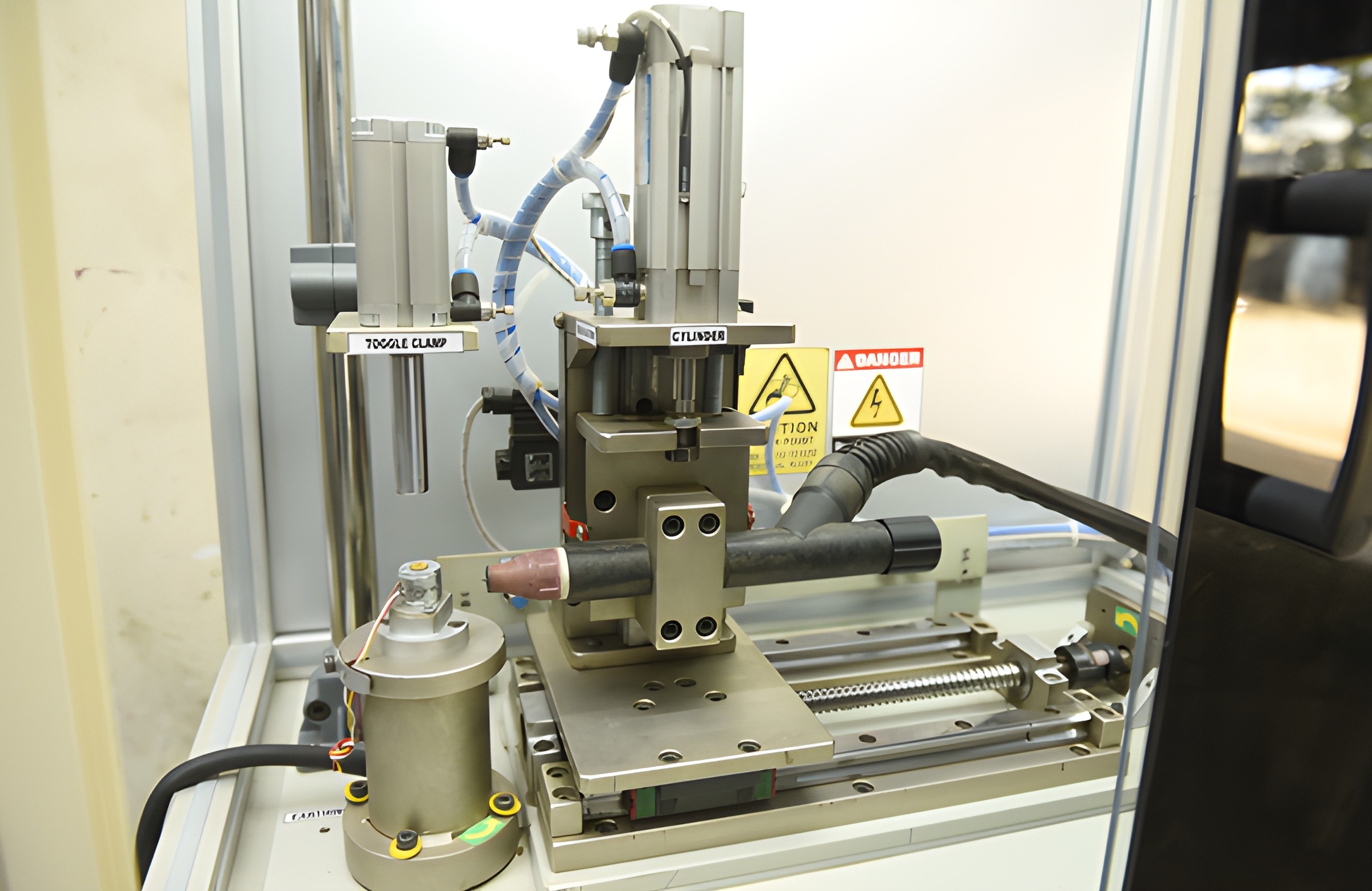

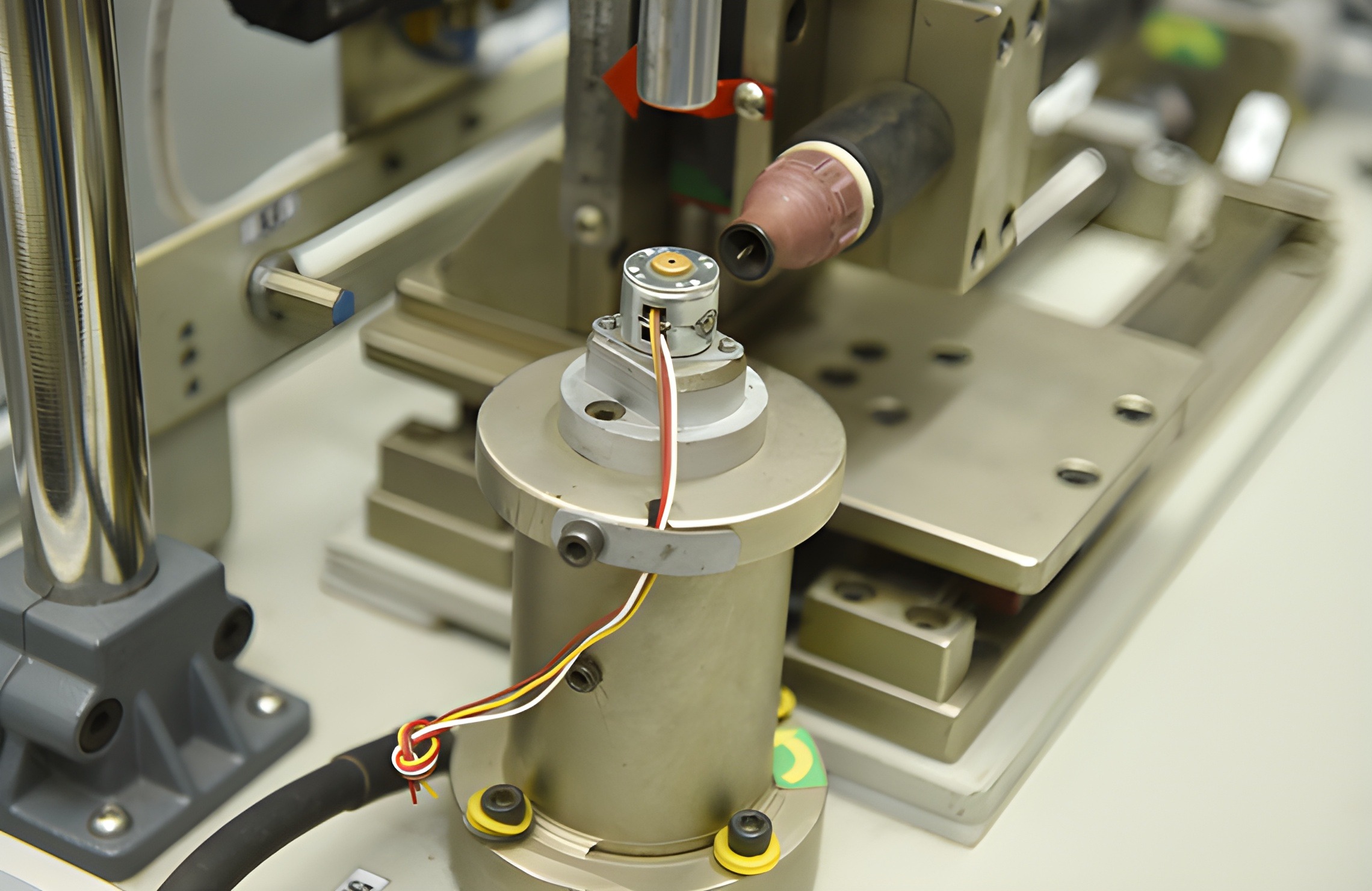

Welding Automation

The welding automation system is designed for the welding of top and bottom part of electrical motor with LM rail based forward and reverse movement. The whole system is control by PLC bsed control panel with HMI.

- servo based 180̊ rotational fixture.

- Welding accuracy upto 40 microns.

- Production rate increased to 2 jobs per min. (increased by 50%)

- Increase of productivity and less dependancy.

- Return of investment within two year, which is cost cutting.

- With welding automation system the company can save upto rs.12,00,000/-* per annual.

Component Rotary Co2 Welding SPM

- MS Sheet Fabricated enclosure with exhaust hood motorized UV Curtains,maintenance door with Safety lock, etc.

- Motorized indexing Mechanism.

- Fixture for holding & locating the component with quick changeover mechanism.

- Application – Cricular profile Welding of component.

- Welding of Cricular Joints.

Rotary TIG/MIG Welding SPM

- MS Sheet Fabricated enclosure with exhaust hood motorized UV Curtains,maintenance door with Safety lock, etc.

- Linear Servo Drive for Torch.

- Linear Seam Welding.

SPOT Welding SPM

- Servo based indexing for components.

- Fixture for holding & locating the component with quick changeover mechanism.

- Application – Circular/Linear spot welding of plates.

- Spot Welding of overlapped or junction plates. Laser Welding SPM

Laser Welding SPM

- MS Sheet Fabricated enclosure with exhaust hood motorized UV Curtains, maintenance door with safety lock, etc.

- Linear Servo (up-down/forward-reverse) for torch, Rotary Indexer for Component.

- Fixture for holding & locating the component with quick changeover mechanism.

- Application – Linear profile Welding of component.

- Spot Welding of overlapped or junction plates.

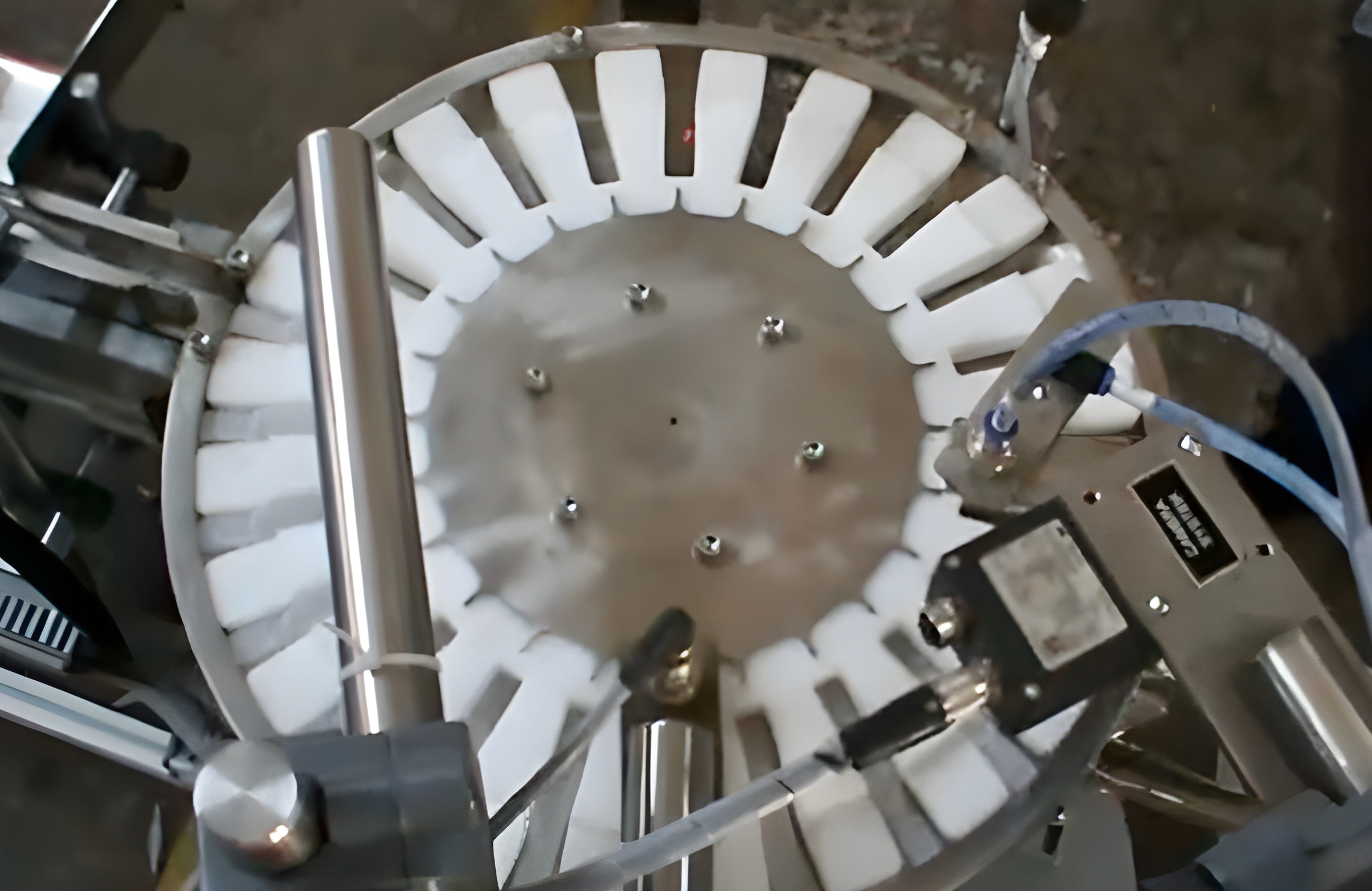

Ampoule Feeding System

The Ampoule feeding system is specially designed to feed the Ampoules at right orientation and right direction with bowl feeder, high speed conveyors & Indexing mechanism with Inspection camera attached at the top of the indexer plate.

- Auto feeding of ampoules with high & low level sensors.

- Smart sensors and rejection unit.

- 80 ampoules per minute can be orient and inspected.

- High resolution standard inspection camera (baumer).

- Auto defect senser with alarm unit.

- PLC control panel with HMI.

- Hopper with elevator conveyor to continuous feed.

- Conveyor belt unit with speed variation and segregation of ampoules.

- Rejection schute to remove excess ampoule.

- 360̊ rotating indexing disc with sensor unit.

- Inspection camera to check right orientation of ampoules.

- Ok not ok gravity schutes with air jet supply station.

- From elevator conveyor through the bowl feeder and transfer to the conveyor track.

- A conveyor transports the ampoules into the tracks.

- A motor driven indexer disc rotates the ampoules certain degree towards the camera inspection station

- The servo driven Indexer turns certain degrees, moving the ampoules into a right position.

- The ampoule segregates into the chutes and forms them into lines from there they continue further.

- Gentle handling to protect the ampoules from damage.

- Adopts servo regulated technology.

- User-friendly due to ergonomic filling height.

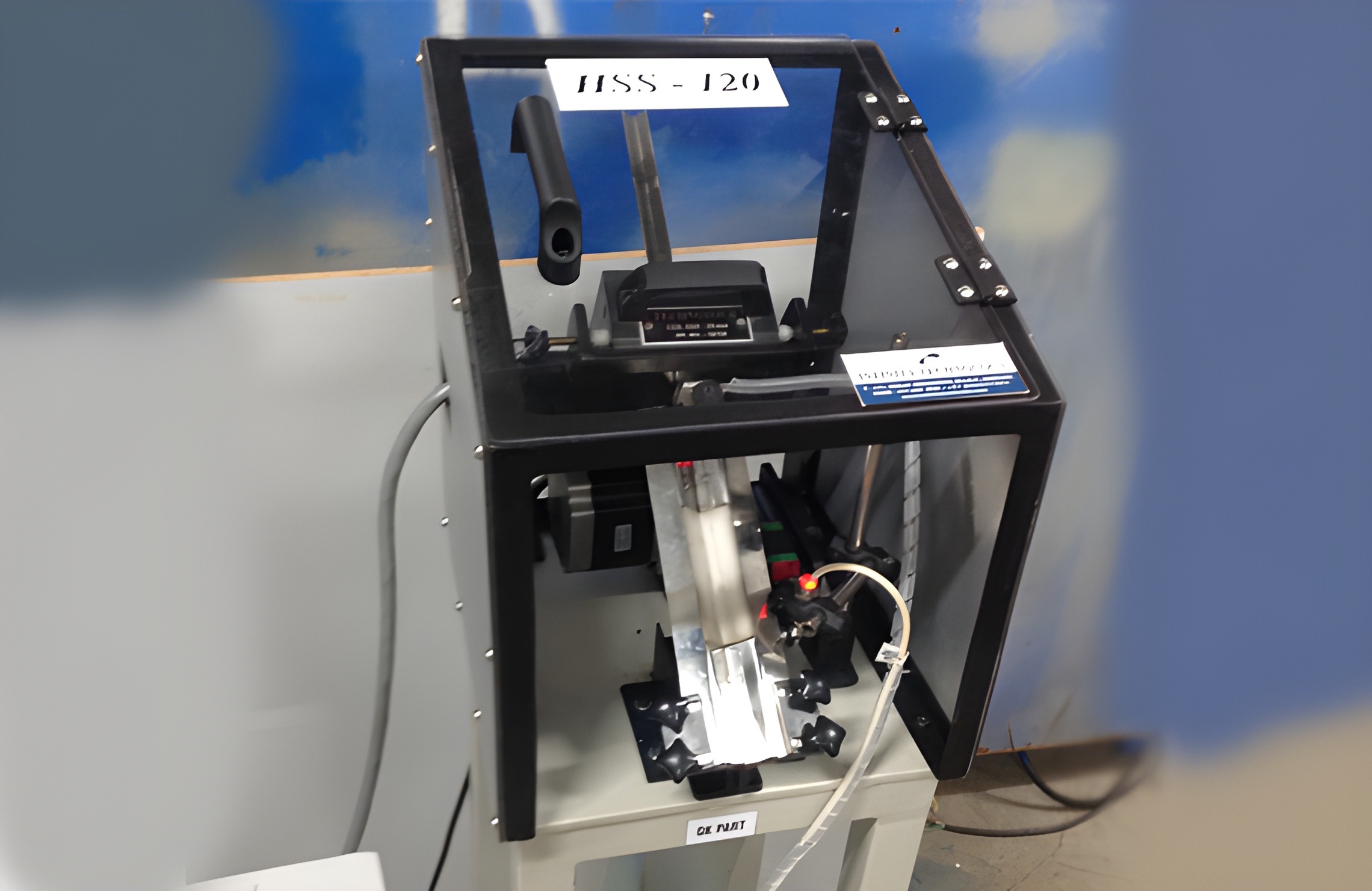

Eddy Current Testing Automation

Full Line Of Portable Flaw Detectors Available To Serve The Broadest Range Of Applications. Perform Highly Reliable Flaw Detection With An Advanced Eddy Current Flaw Detector. Simplicity & Reliability. Leading Technologies support by infinity Technology with service and support team.

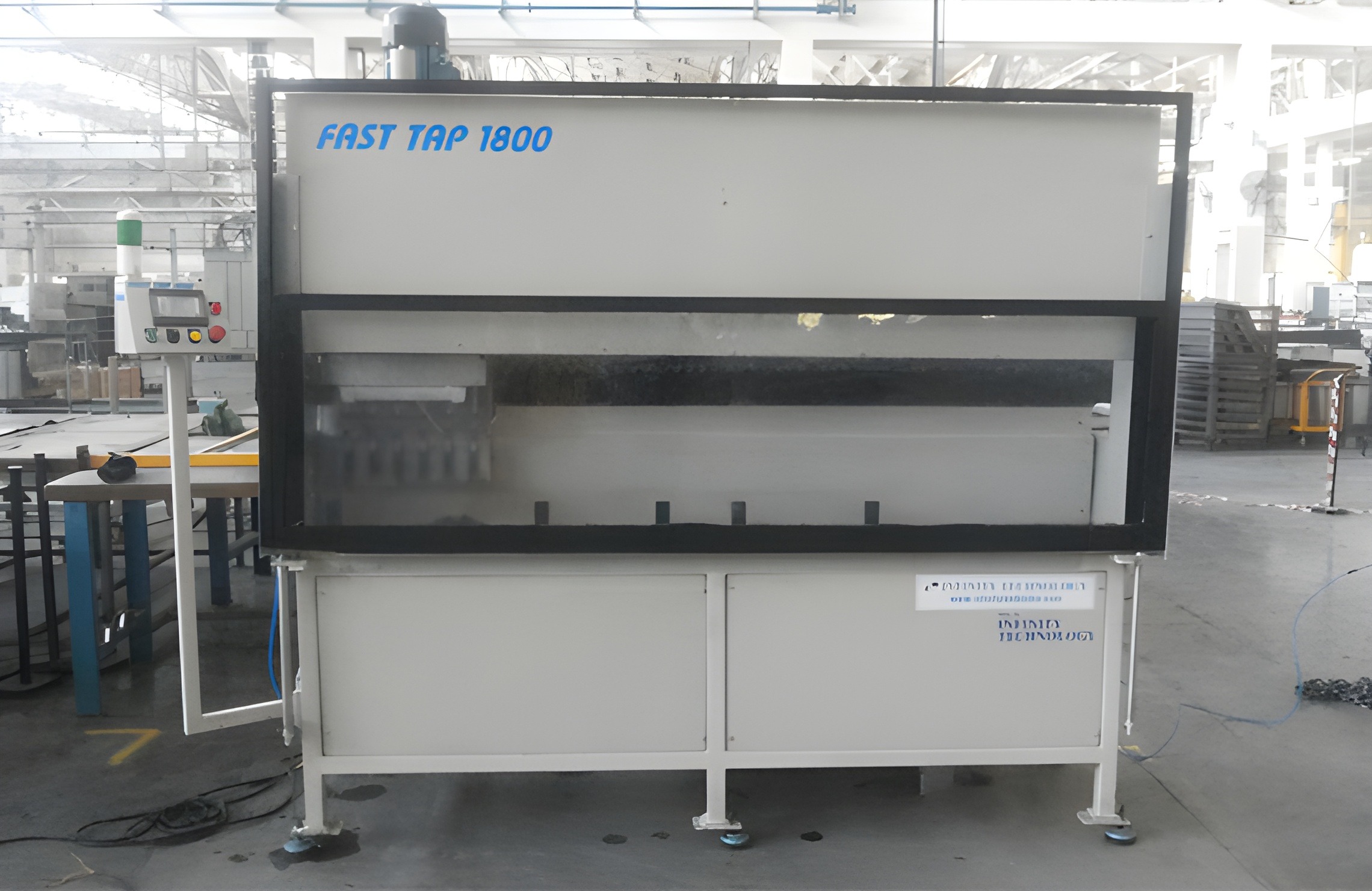

Multi Spindle Tapping Machine

Features

- Low maintenance

- Sturdy design

- Hassle-free performance