INDUSTRIAL WASHING MACHINE

INDUSTRIAL WASHING MACHINE

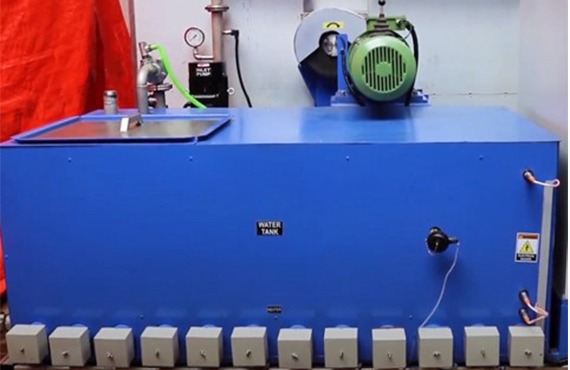

- Compact Design

- Hot Water Spraining Nozzle

- Temperature Controlling System

- Complete ss Fabrication structure

- PLC Control Panel with HMI

- Manual Loading Unloading

- Auto water Inlet and Outlet drain system

- 1200 Ltr Water Tank

- 2 Inch Water Pipeline

- 3 Inch Drainage Water Pipeline

- Auto Drainage System

- SS Structure Cage for bin carrying 12 Quantity

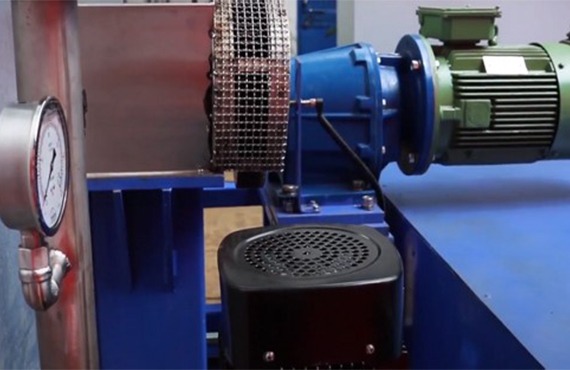

- V Belt Pulley Drive Mechanism

- 40 KW Heater Provision for water heating to maintain upto 55 degree Celcius in One Hour

- Cleaning Velocity 32 RPM

- Loading Unloading Manually.

- Spraying Nozzle Working Presurre 3 Bar.

- Internal Structure S.S 304 Outer Frame M.S.

- Temperature setting time 20MIN, Cleaning time will be setable.

- PLC Base Control Panel with HMI.

- Rigid & Roboust Structure.

- Hinge Door with sealing.

- Cycle Operation 15 min depends on trial

- SS Water Tanks

- TDS Meter

- Flow Meters

- Level Switches and Indicators

- Water Filtration Units

INDUSTRIAL WASHING MACHINE

- Loading of 16 trays manually into slots (4 per slot).

- Tray movement managed by manual + PLC control from 0° to 180°.

- Washing process starts with tray rotation in clockwise and anti-clockwise direction.

- Integrated dry air system activates for hose drying.

- Water heating managed by steam in SS tubes.

- Sensors and meters monitor water quality, level, and temperature.

- Used water is filtered, drained, and recycled automatically.

- All operational data is recorded via data logging system.

- Automotive components cleaning

- Rubber hose industry

- Plastic bin reuse operations

- Food processing and packaging

- Chemical and pharma container cleaning