BLOGS

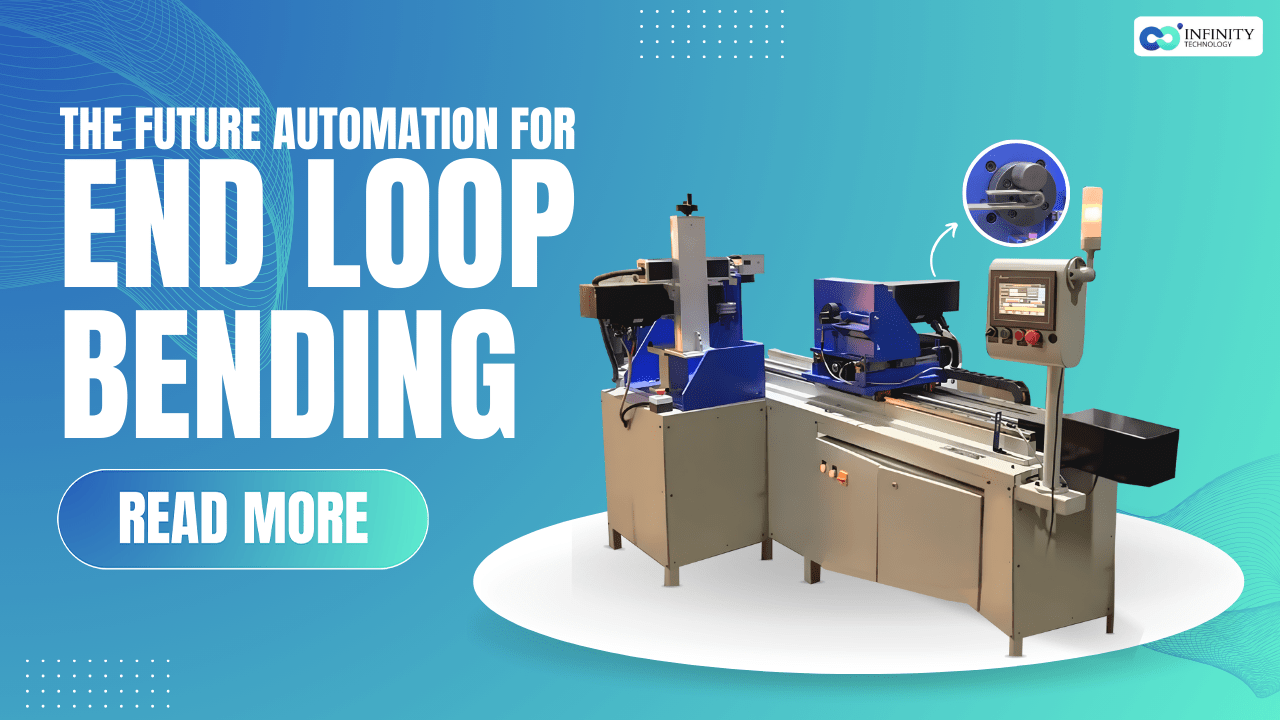

Revolutionize your loop end production with Infinity Technology’s innovative End Loop Bending machines! From cotton mops to spectacle chains, our machines deliver unparalleled efficiency and precision in creating flawless End Loop Bendsfor a wide range of products.

The Power of Automation in End Loop Bending Manufacturing:

- Unmatched Speed: Produce end loop at high speeds, significantly boosting your production output.

- Consistent Quality: Eliminate human error and ensure uniform, high-quality loop ends every time.

- Reduced Labor Costs: Automate the end loop creation process, minimizing labor requirements.

- Increased Versatility: Handle various loop end types with ease, from simple loops to complex configurations.

Infinity Technology: Your One-Stop Shop for End Loop Bending Machines:

- End Loop Bending Automation Machines: Produce perfect loop ends for mops of all sizes and materials with our specialized machines. (e.g., Loop mop machine)

- End Loop Bending Machines: Create consistent loop ends on cclamps efficiently, ensuring a secure and professional finish.

- Spectacle End Loop Bending Machines :Manufacture precise loop ends for spectacle clamps, guaranteeing a comfortable and functional fit.

Beyond the Basics: Applications for End Loop Bending Machines:

- High Precision Bends: End loop bending machines utilize tooling that precisely shapes the material during the bend. This ensures consistent and accurate bends throughout every clamp produced, reducing inconsistencies and improving overall quality.

- Repeatability: These machines offer a high degree of repeatability. Once the bend profile is programmed, the machine can consistently replicate it on every clamp, minimizing the need for manual adjustments and ensuring a uniform product.

- Increased Production Rates: End loop bending machines are often faster than manual bending methods, which can significantly boost production speed. This translates to increased output and potentially lower production costs per clamp.

- Reduced Labor Costs: Automation with end loop bending machines reduces the reliance on manual labor for bending tasks. This can free up workers for other tasks or potentially reduce overall labor costs.

- Improved Ergonomics: Bending metal by hand can be physically demanding. End loop bending machines eliminate the need for manual bending, improving worker safety and ergonomics.

- Versatility: These machines can often handle a variety of clamp materials and thicknesses, making them suitable for manufacturing a wider range of clamp types.

Infinity Technology: Best solution to End Loop Bending Innovation in Clamp Manufacturing

At Infinity Technology, we are passionate about developing cutting-edge automation solutions for the end loop automation manufacturing industry. Our loop end machines empower businesses to achieve remarkable efficiency, exceptional quality, and unmatched production speed.

Contact us today to discuss your end loop production needs and discover how Infinity Technology can revolutionize your operations!