CONVEYOR MACHINES

PVC Belt Conveyor

Features

- Durable PVC Belt : Resistant to moisture and chemicals.

- Versatility : Suitable for various materials and applications.

- Smooth Operation : Provides reliable item transport.

- Low Maintenance : Easy to clean and maintain.

- Adjustable : Allows for height and speed adjustments.

- Cost-effective : Economical compared to other conveyor types

Technical Specification

- Durable PVC Belt : Resistant to moisture and chemicals.

- Versatility : Suitable for various materials and applications.

- Smooth Operation : Provides reliable item transport.

- Low Maintenance : Easy to clean and maintain.

- Adjustable : Allows for height and speed adjustments.

- Cost-effective : Economical compared to other conveyor types

Chain Drive Conveyor

Features

- Operationally Safe

- Energy efficient

- Reliable ( Parts a-nd components engineered to last)

- Adaptable to changing needs

- Motor and Gearbox

- Duplex chain with sprocket

- Rigid and robust structure

Technical Specification

- Chain Type and Size:

1. Specify roller chain or flat top chain.

2. Detail chain pitch and width dimensions. - Load Capacity

1. Define maximum load capacity per unit

2. length and overall.

3. Consider static and dynamic load requirements - Drive System:

.1. Specify chain drive type.

2. Detail motor specifications: power rating,

3. voltage, frequency.

Roller Conveyor

Features

- Efficient Material Transport : Utilizes rotating cylinders (rollers) for seamless movement, minimizing friction.

- Versatile Configuration : Adaptable to diverse layouts and product types, enhancing operational flexibility.

- Robust Durability : Built with sturdy materials for long-term reliability and minimal maintenance needs.

Technical Specification

- Define roller diameter and material for reliable durability and efficient product handling.

- Specify frame dimensions and load capacity to optimize space use and operational performance.

- Select the suitable drive system (e.g., motorized or gravity-fed) for precise control and energy efficiency.

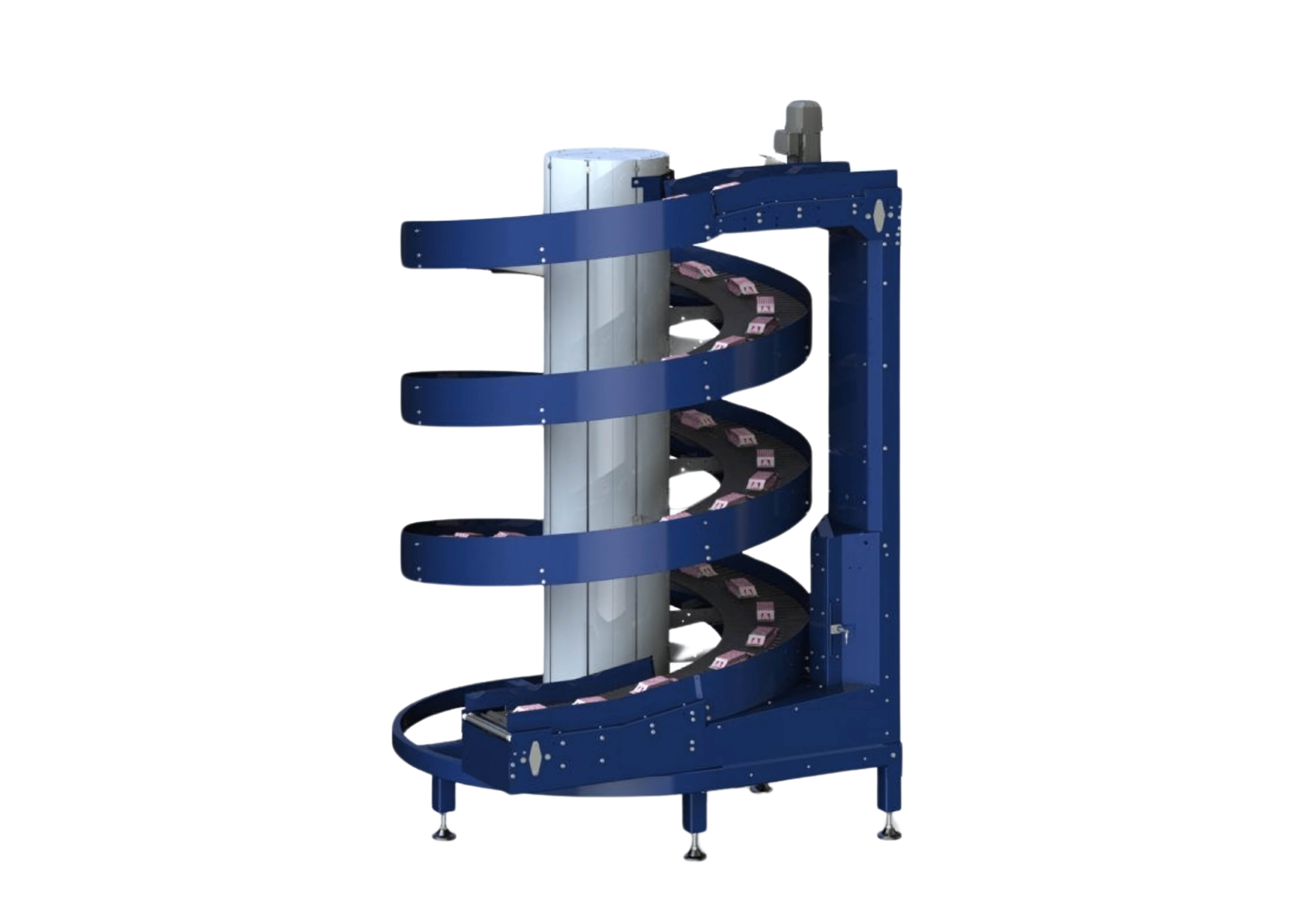

Spiral Conveyor

Features

- Vertical Efficiency: Moves goods vertically to save space and optimize layout.

- Configurable Direction: Supports both upward and downward transport to fit different facility designs.

- Variable Speed Control: Adjusts speed for diverse product handling needs, enhancing throughput.

- Reliable and Low Maintenance: Engineered for durability with minimal upkeep, ensuring consistent performance.

Technical Specification

- Vertical Transport Efficiency : Facilitates continuous upward or downward movement, maximizing space utilization.

- Compact Footprint : Minimizes floor space requirements, ideal for efficient facility layout.

- Variable Speed Control : Allows for flexible handling of diverse products and adjustable throughput.

Side Wall Belt Conveyor

Features

- Allows for steep inclines, enabling efficient vertical transport of materials.

- Side walls prevent materials from slipping or spilling during transportation.

- Adaptable to various spatial constraints and production needs due to its compact design.

- Handles delicate materials gently, reducing product damage.

Technical Specification

- Adjustable Side Walls: Allows customization for securely guiding various materials of different sizes.

- Robust Design: Engineered for heavy-duty applications, ensuring durability and reliable performance.

- Variable Speed Control: Provides flexibility in material handling, accommodating different production speeds and requirements.

Pallet Conveyor

Features

- Modular Design: Allows for easy customization and scalability.

- Automation Capabilities: Enhances efficiency through automated pallet handling.

- Compatibility: Accommodates various pallet sizes and types.

- Safety Features: Includes sensors and guards for safe operation in industrial environments.

Technical Specification

- Load Capacity: Supports pallets weighing up to [specify weight].

- Speed: Operates at adjustable speeds ranging from [specify range] meters per minute.

- Dimensions: Configurable to accommodate pallet sizes of [specify dimensions

- Drive System: Utilizes [specify type of drive system] for reliable and efficient operation.

Rubber Belt Conveyor

Features

- Robust Construction: Utilizes durable rubber and reinforced materials for longevity.

- Versatile Applications: Ideal for a variety of industries and materials.

- Efficient Handling: Facilitates smooth and continuous material transport.

- Adjustable Settings: Offers flexibility with adjustable speed and incline configurations.

Technical Specification

- Belt Material: High-grade rubber compound for durability and traction.

- Capacity: Handles up to [specify capacity] tons per hour.

- Drive System: Powered by [specify motor type and power].

- Dimensions: [Specify length, width, and height] for customizable installations.

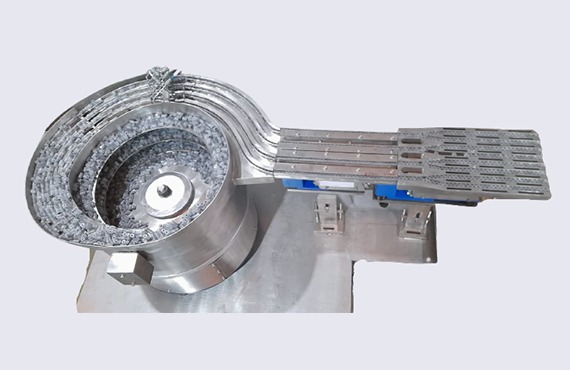

BOWL FEEDER

Bowl feeders are common devices used to Feed small component to another machine one-by-one, also known as Vibratory Feeder. INFINITY manufactures 6 models of vibratory Bowl Feeders, i.e ITB – 200, ITB – 300, ITB – 400, ITB – 500, ITB – 600, ITB – 800. We follow stringent Safety Norms for Machinery Safety, Low Voltage Directive as well as the Electro Magnetic Compatibility.

| Model Name | Bowl Diameter | Coil Power | Controller Type |

|---|---|---|---|

| ITB 200/300 | 200/300 mm | 170 VA | Digital |

| ITB 400 | 400 mm | 510 VA | Digital |

| ITB 500 | 500 mm | 680 VA | Digital |

| ITB 600 | 600 mm | 680 VA | Digital |

| ITB 800 | 800 mm | 1000 VA | Digital |

PRODUCT DEVELOPED THROUGH EXPERIENCE

Our Bowl Feeders are an outcome of our own experience while designing our SPM’s. Our Technicians are experienced to handle components which are most difficult to orient and require high feeding rate. We welcome comments which other vibratory feeder manufacturers decline. INFINITY represent a complete range of vibratory bowl feeders available, including drive units, bowls, bowl centres, control boxes and additional accessories

APPLICATIONS OF VIBRATORY BOWL FEEDER

Bowl Feeders are Suitable for feeding components for subsequent operations on special machines in, mechanical, pharmaceutical, electrical, bearing and many other industries. The components can be plastic switches, bullets heads, capsules, rubber cots, shaving handles as well as heavy parts such as fasteners, bolts, bearings, races and metal sockets. We offer a total design solution for components to be handled, from tooling for variation in components, and Manufacturing services for custom vibratory Feeders.