CLAMP MACHINES

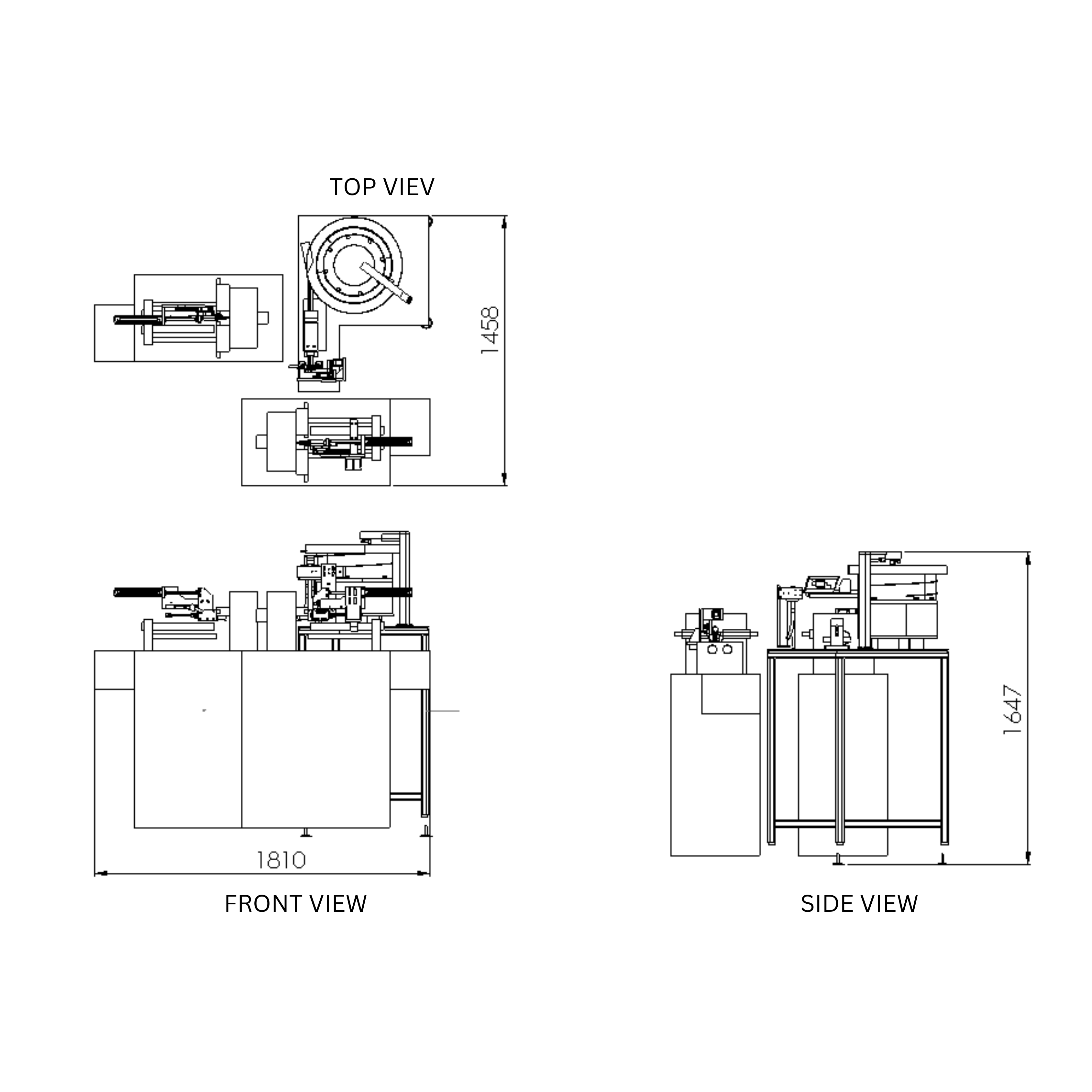

GROOVING Automation MACHINE

Features

- Job loading bowl feeder

- Auto signaling mechanism for feeding 2 systems

- Pneaumatic loading mechanism

- Accuracy within 0.2 mm

- Auto ejection system

- Plc control panel

- For two mechanism 12 rpm output

- Hp 2

- Manless operation

- Rigid & robust structure

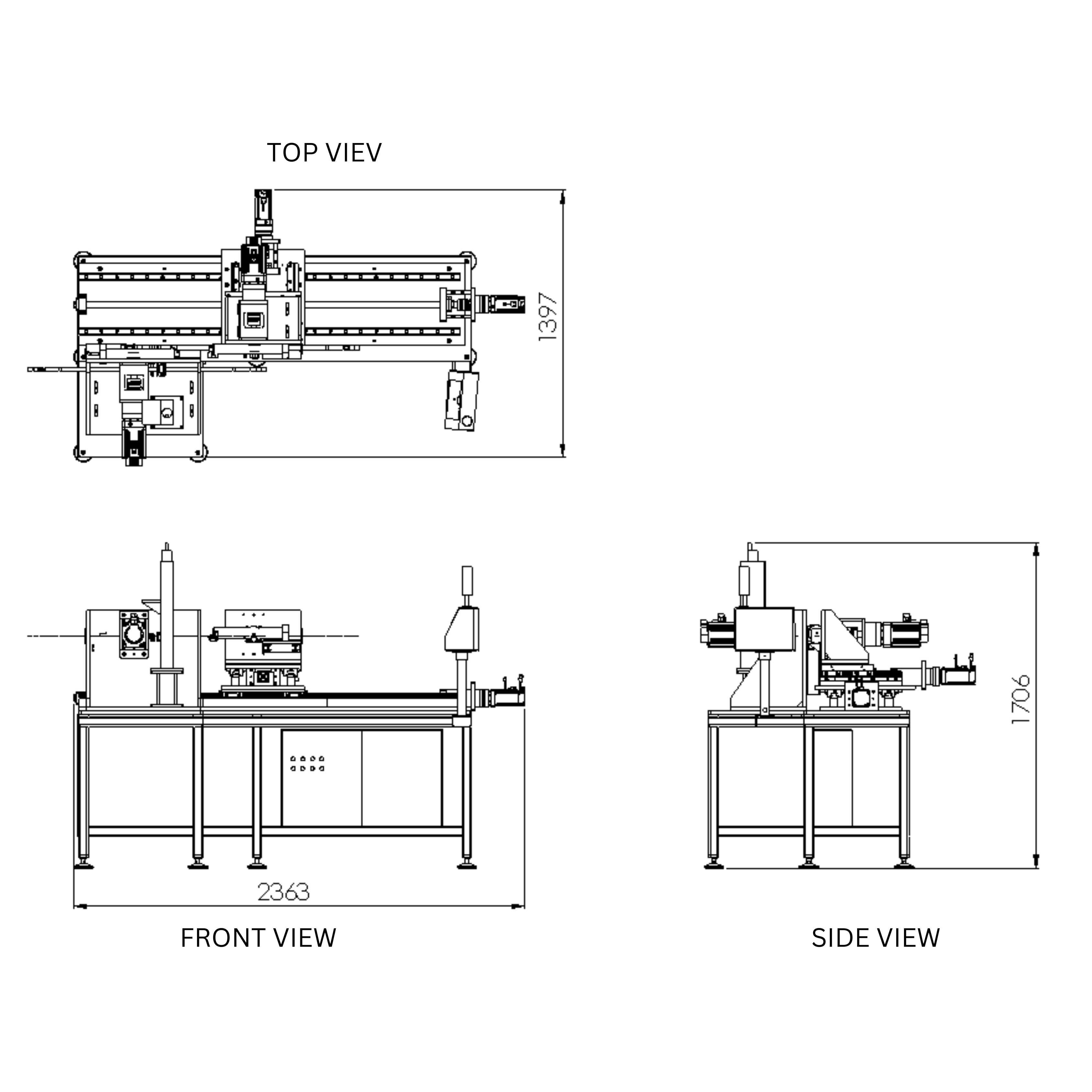

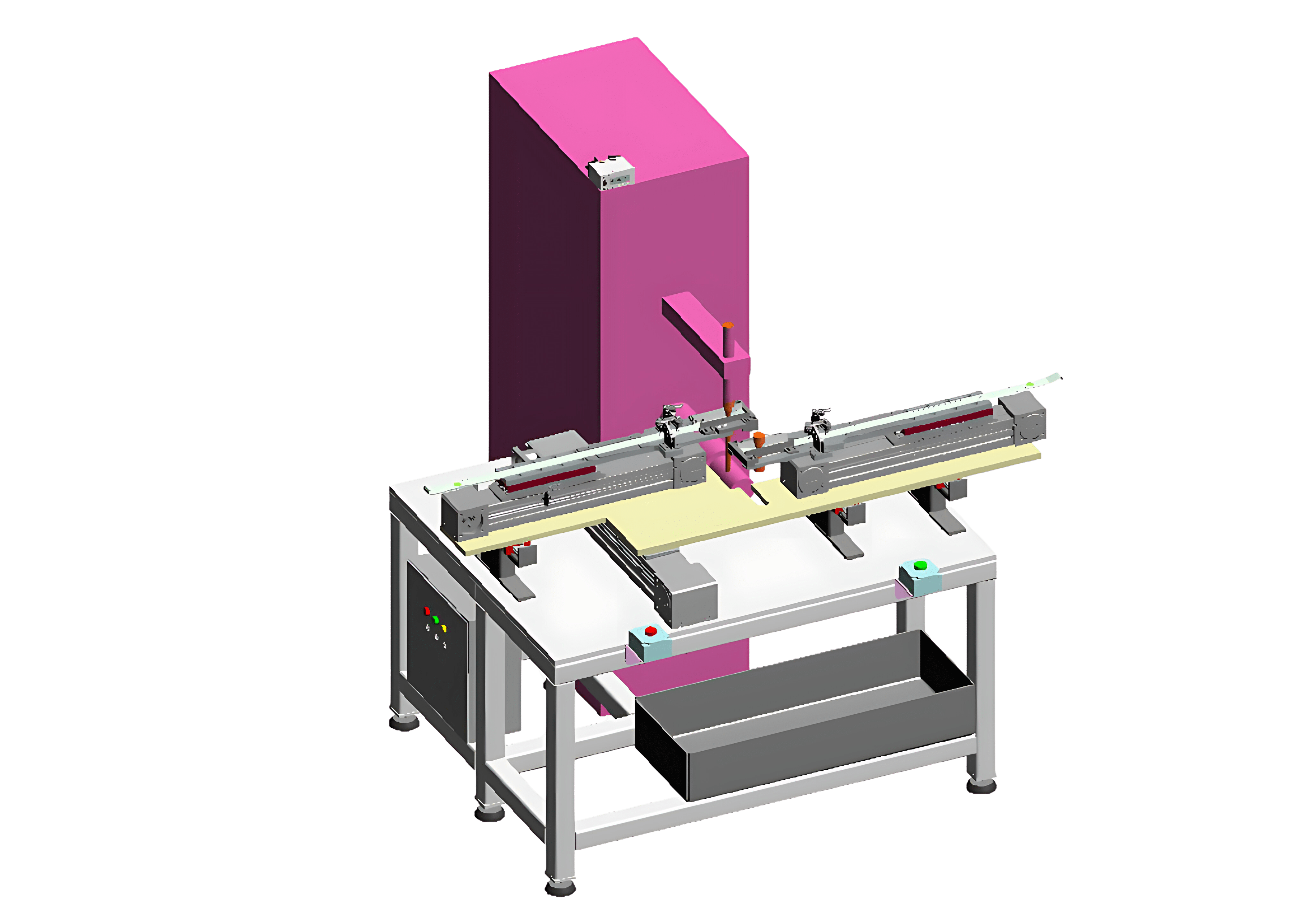

END LOOP BENDING MACHINE

Features

- Auto adjust strip length & bends ends ( servo based)

- Laser marking

- Machine operates at 10ppm

- PLC with

- HMI controller

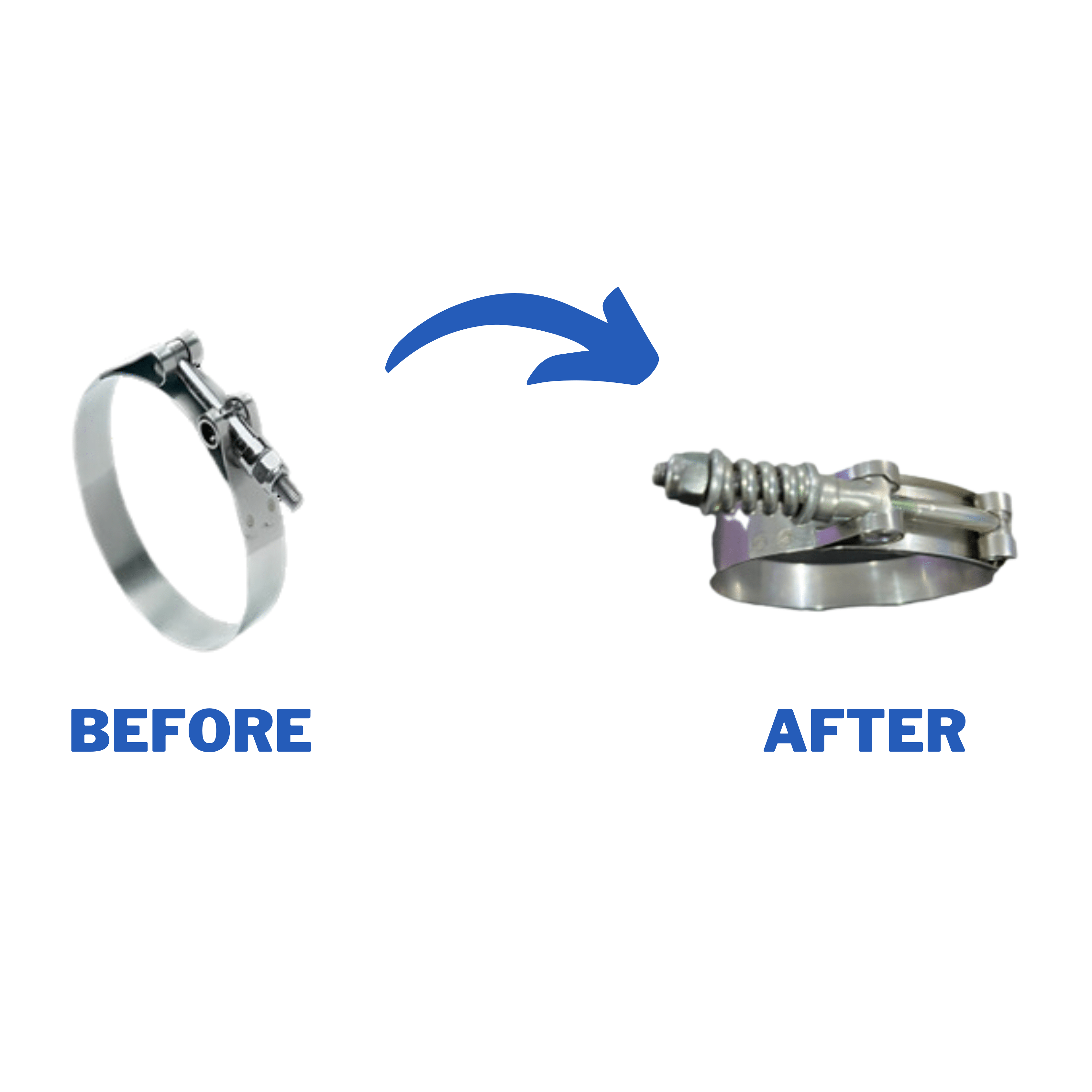

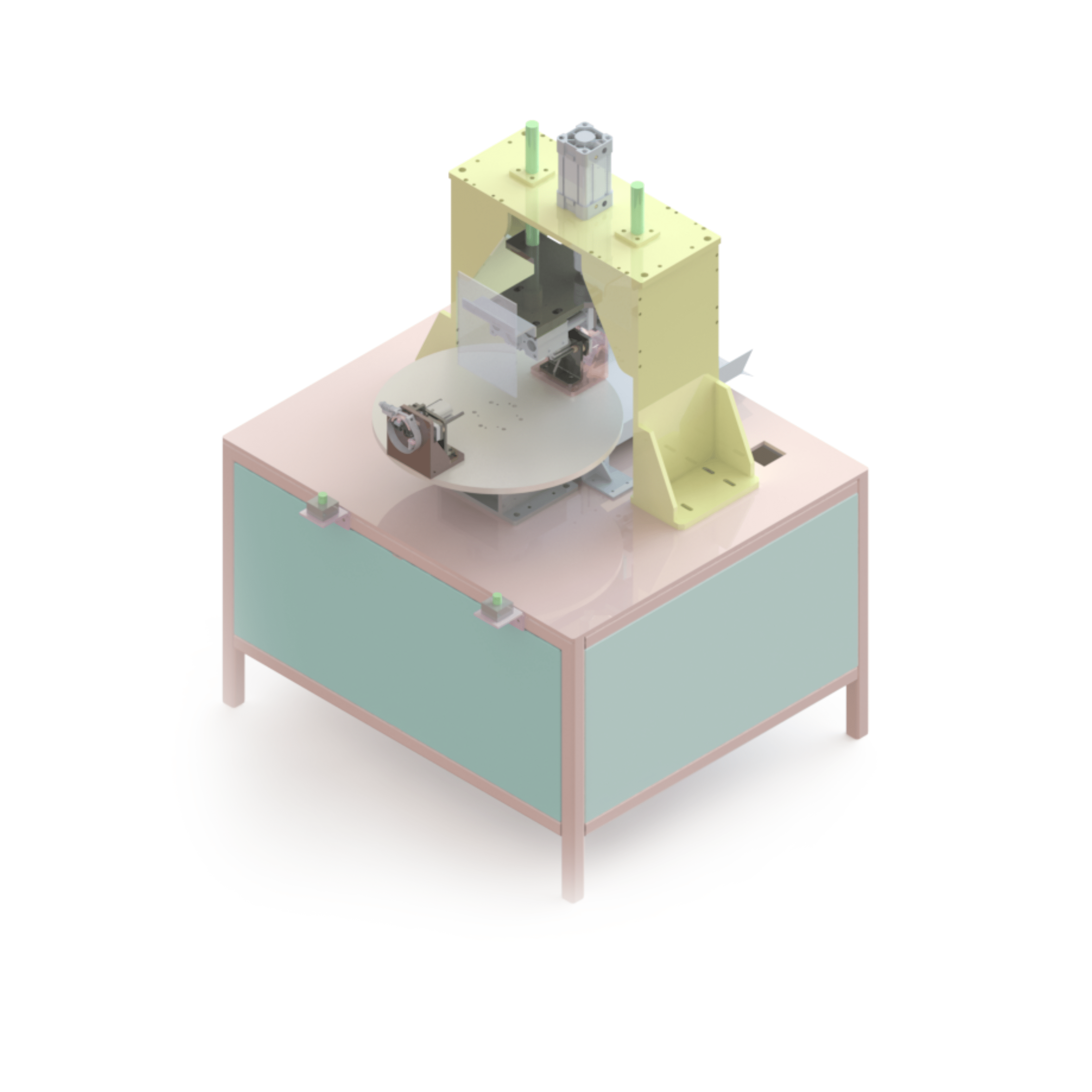

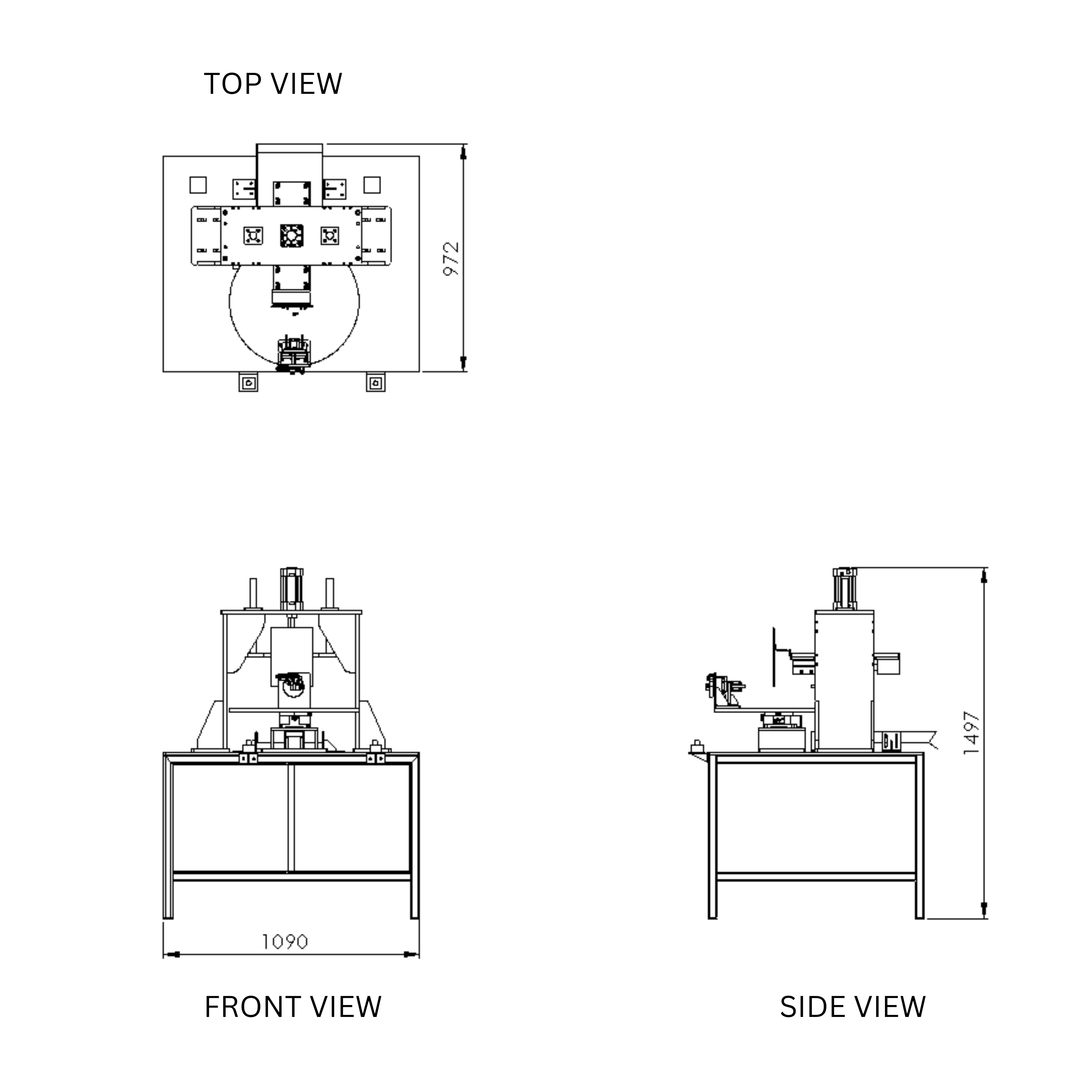

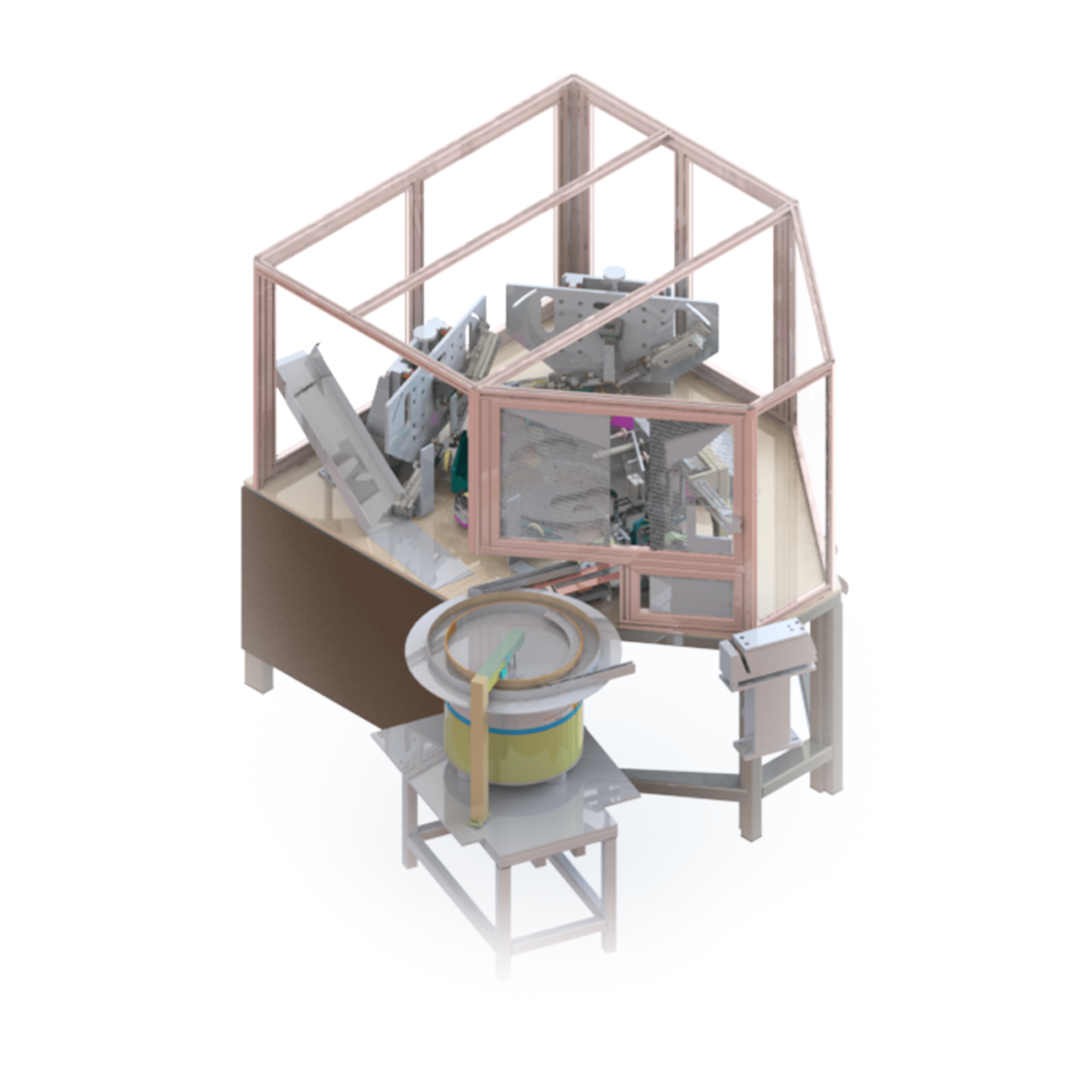

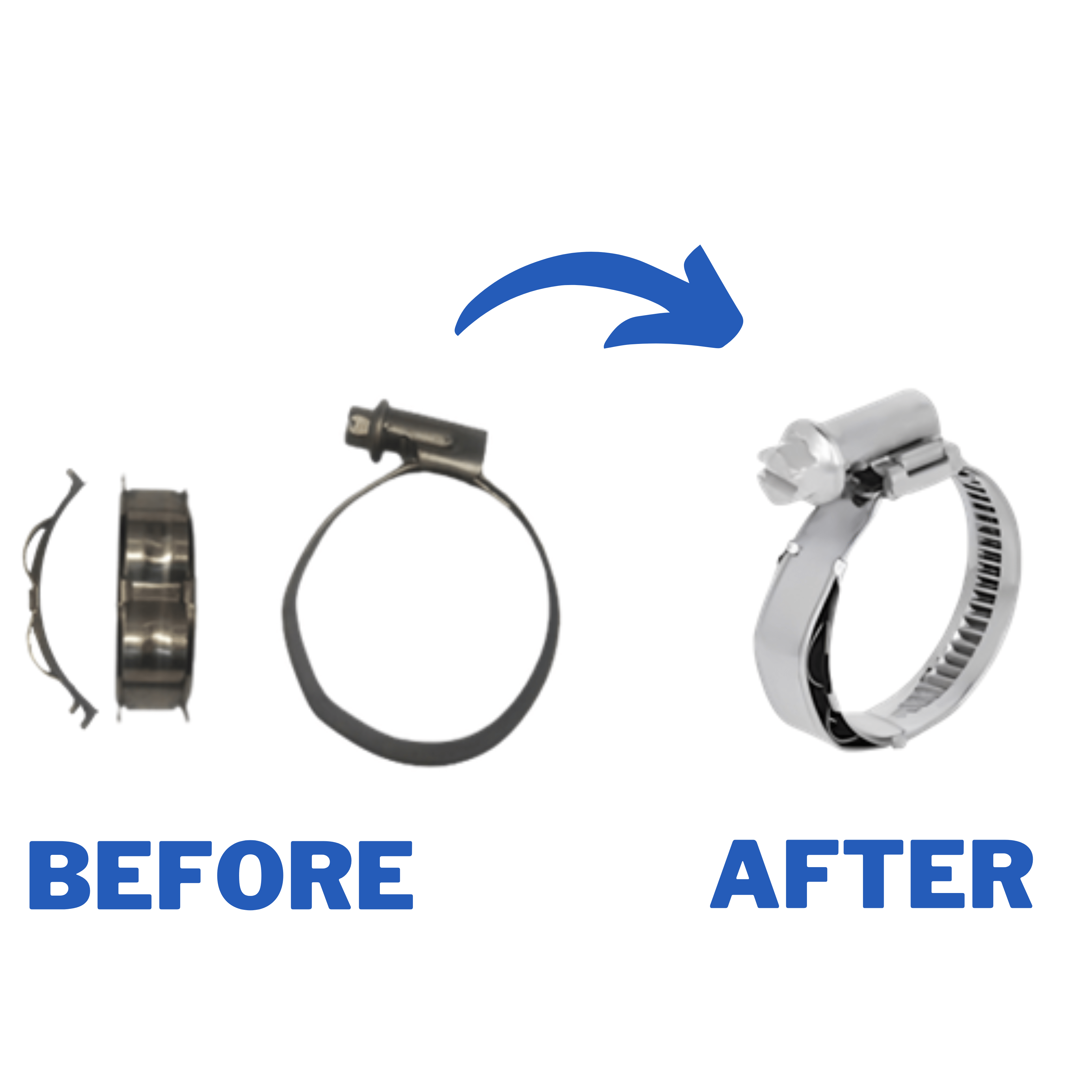

SPRING CLAMP AUTOMATION MACHINE

Features

- Rotating fixture assembly for the clamp assembly

- Repeatability in assembly of the clamps

- 0% Error while assembly

- User-Friendly Interface

- Modular Design

- Incorporates safety mechanisms to protect operator

- Mechanism to ensure precise placement of each component

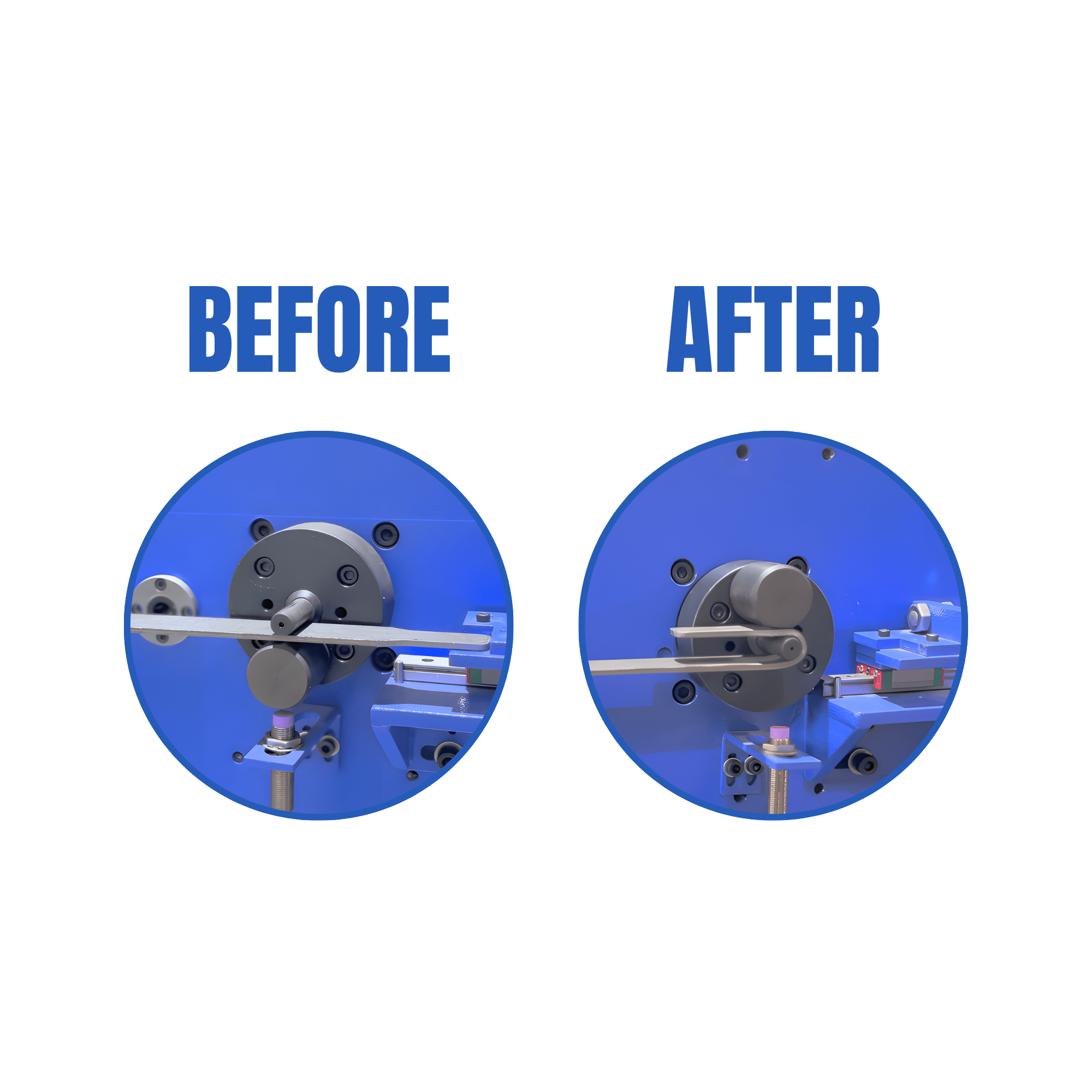

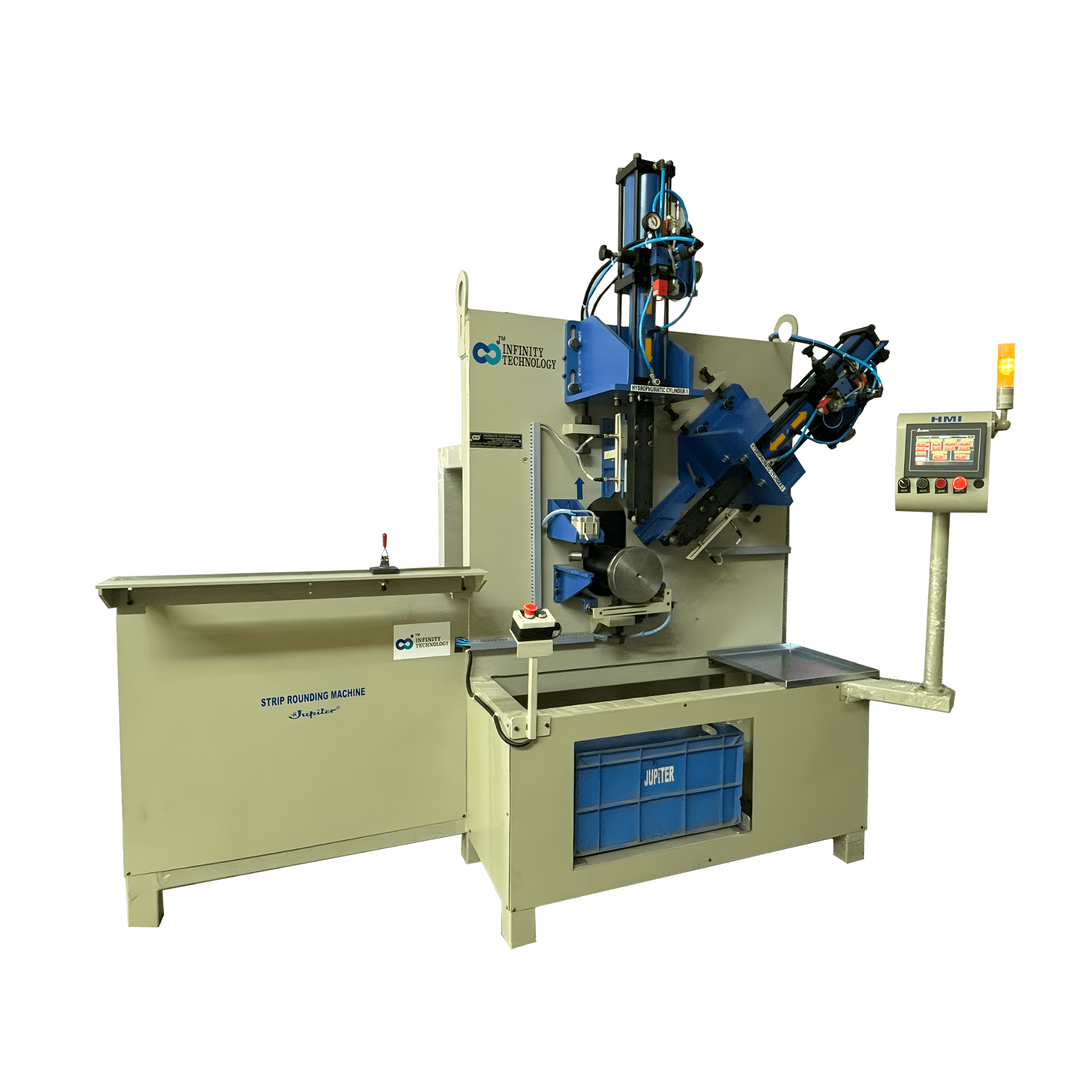

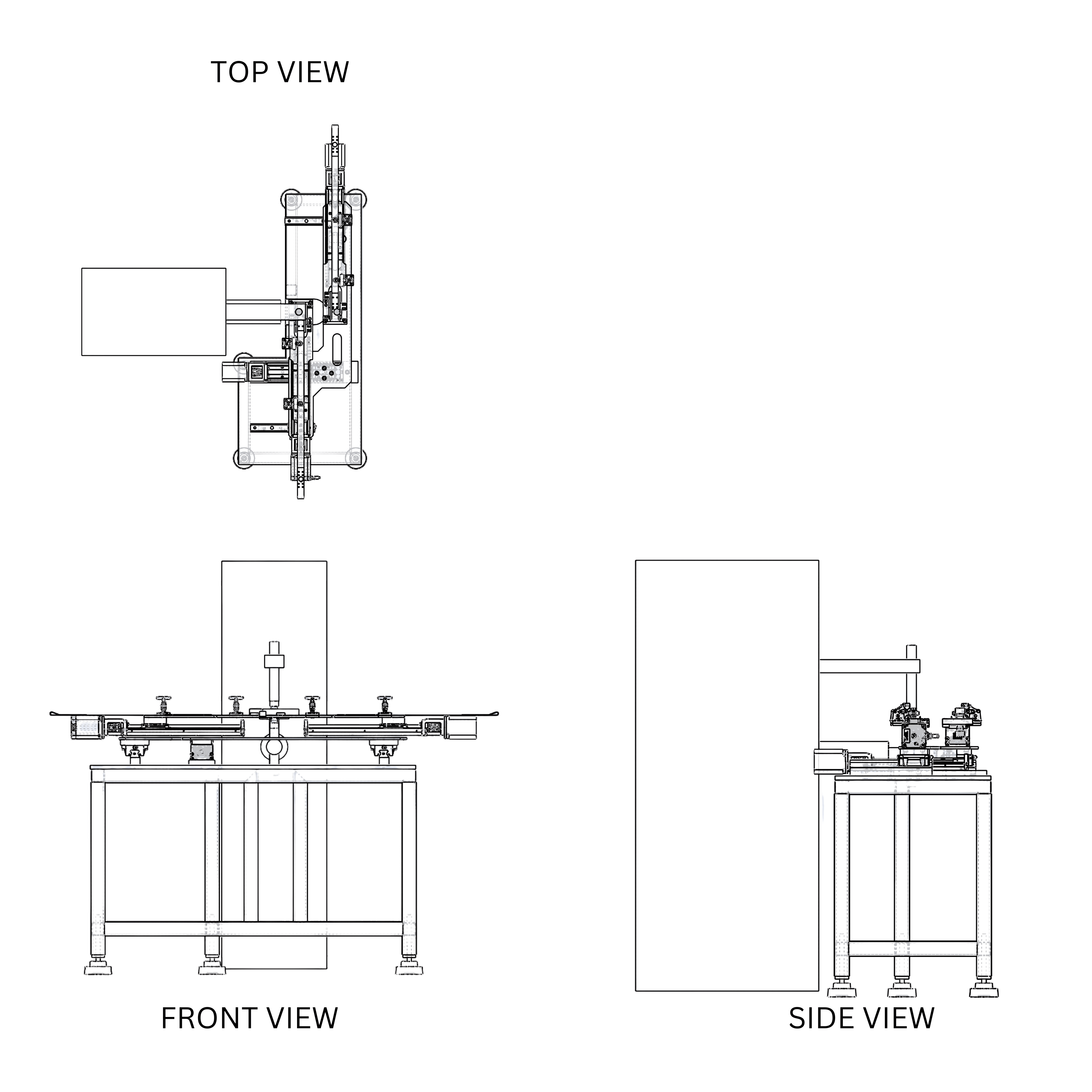

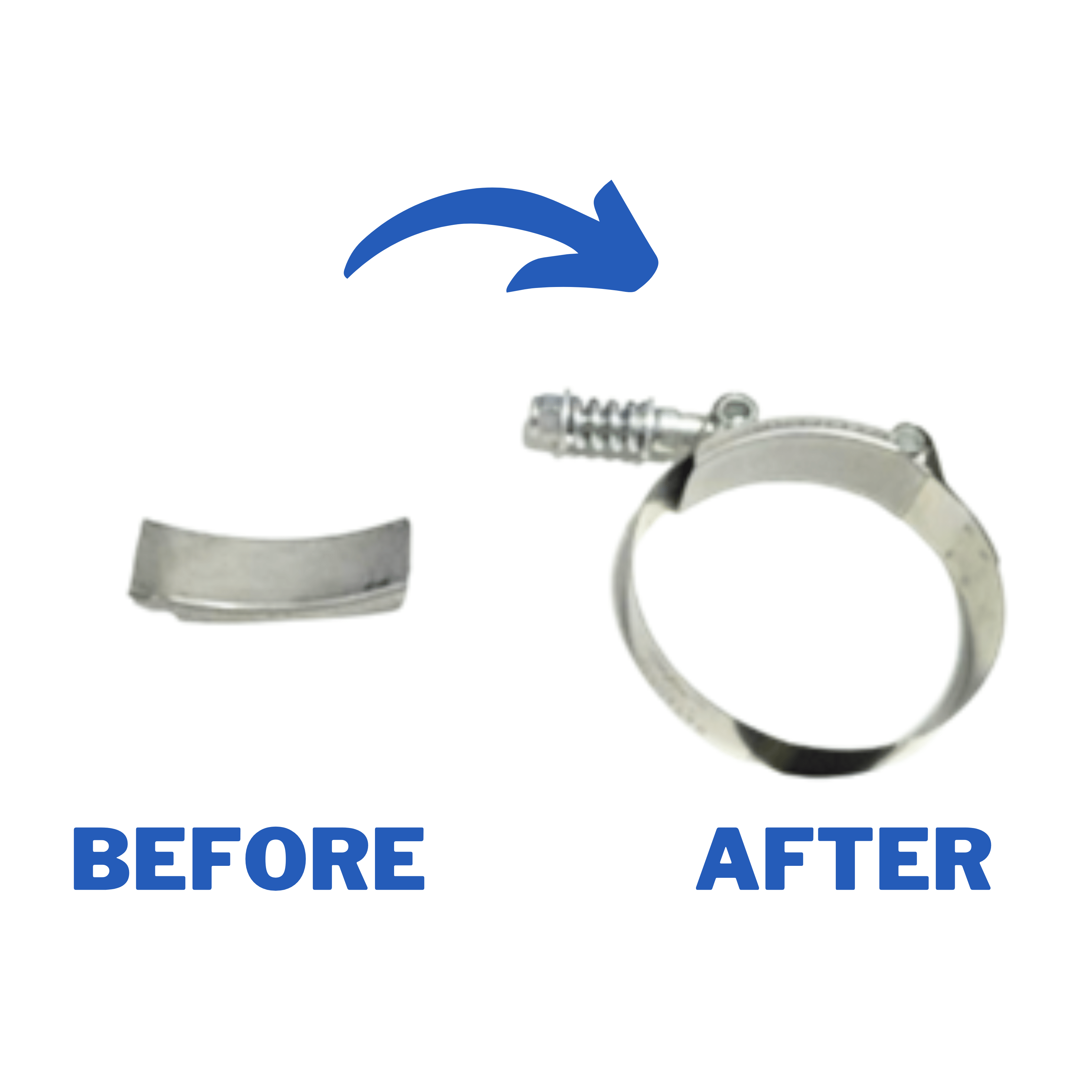

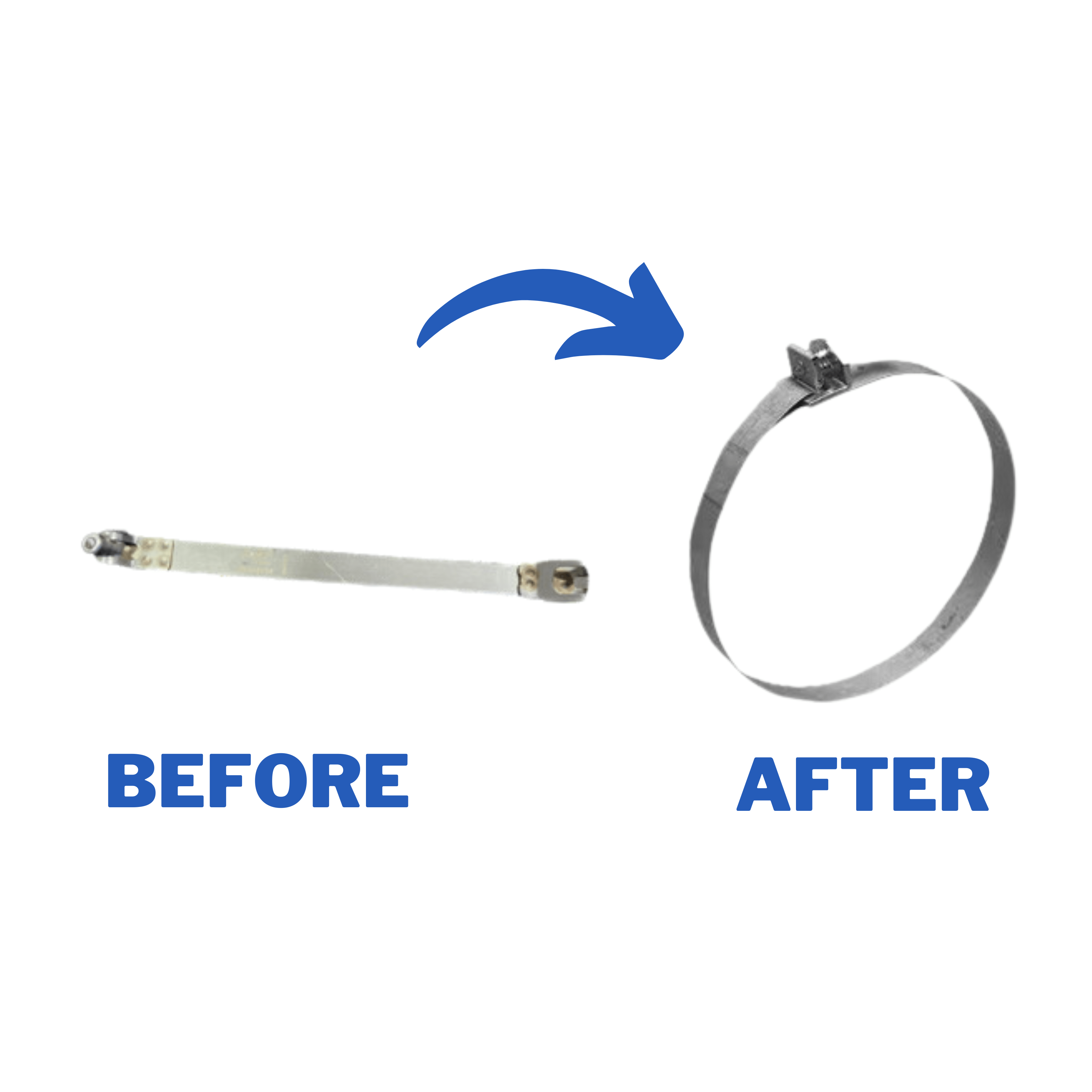

STRIP ROUNDING MACHINE

Features

- Precise& consistent clamps

- Faster rounding

- Reduced cycle time

- Machine output 8 – 10 ppm (in single line)

- Servo motor drive

- Adjustable from 50 mm to 350 mm

- PLC with HMI control panel

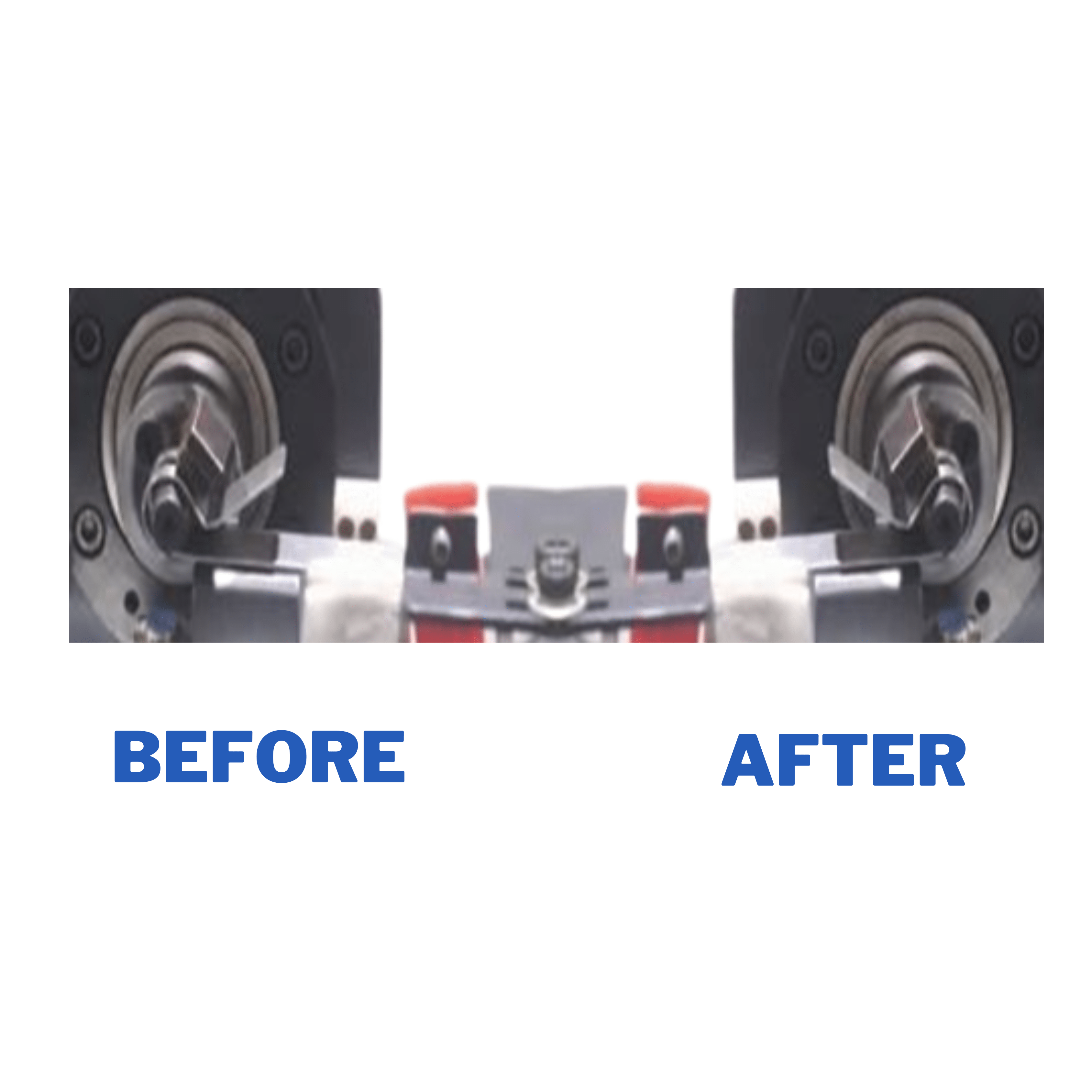

bridge chrimping machine

Features

- Fixture assembly guarantees accurate and repeatable crimping operations.

- Indexing unit enhances efficiency, accuracy, and productivity in crimping.

- Crimping station automates crimping or compression at a rate of 12 ppm.

- Precision design ensures consistent and reliable crimping performance

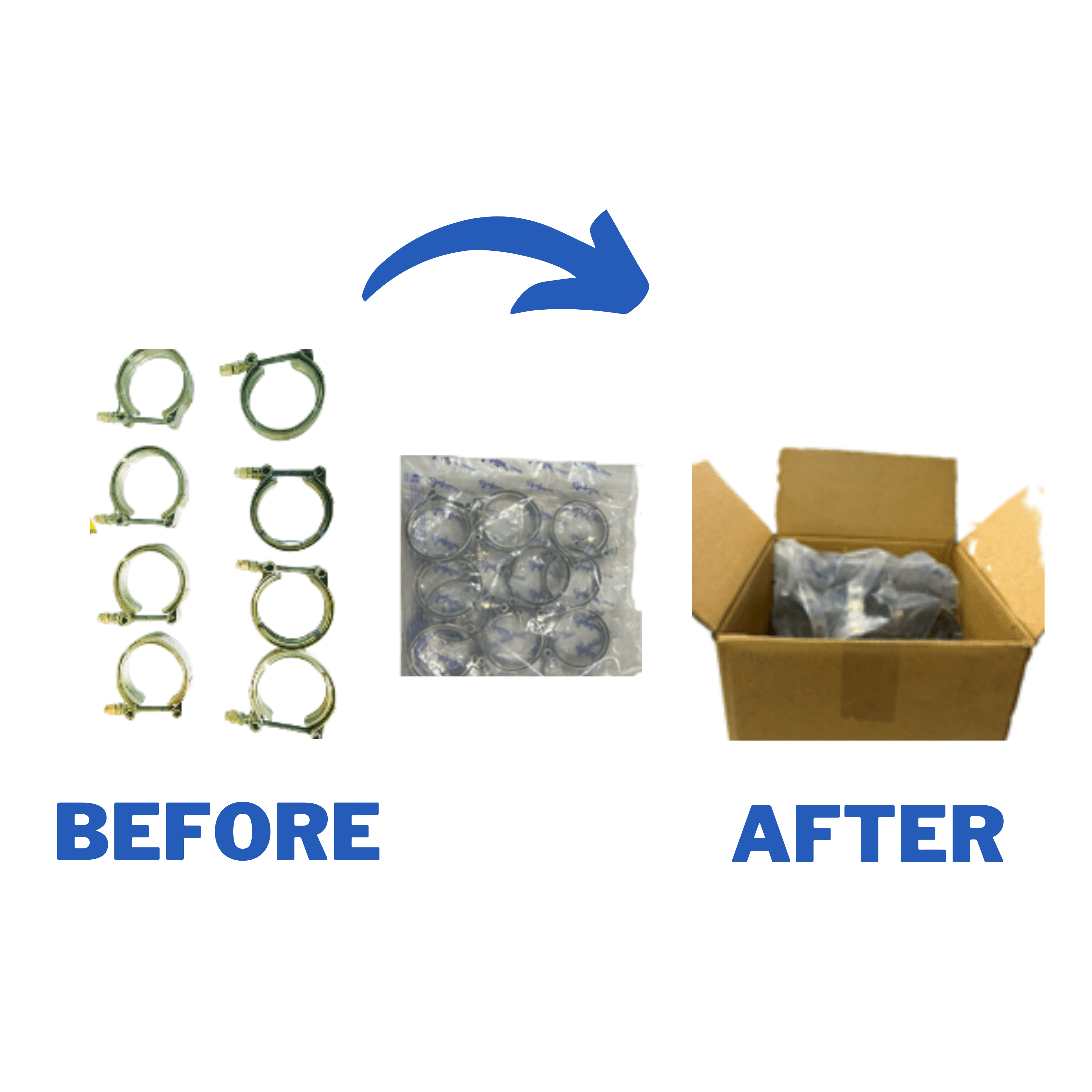

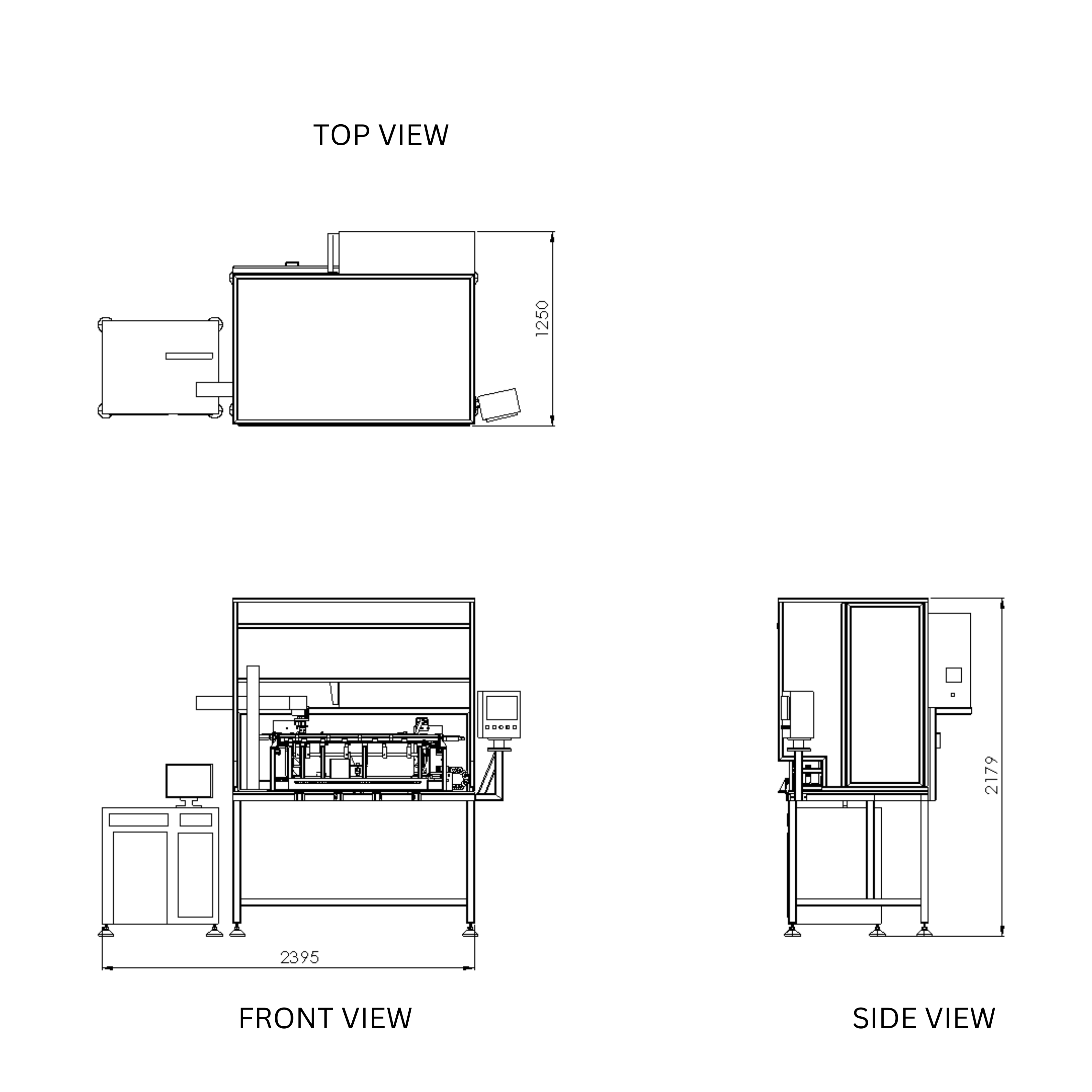

JOB COUNTING & SORTING SYSTEM machine

Features

- QR code verification: Ensures the correct part is loaded before filling.

- Pusher mechanism: Rejects incorrect parts for quality control.

- Precise bag filling: Two stations fill bags with the exact amount of components.

- QR code labeling: Guarantees parts are identified for tracking.

- Final QR code scan: Verifies the completed bag has the correct components.

END LOOP FORMING & LASER MARKING

Features

- Servo based slider mechanism for strip length adjustment

- Chain drive unit with holding fixtures

- Motorized loop forming unit

- Auto ejection by pneumatic system

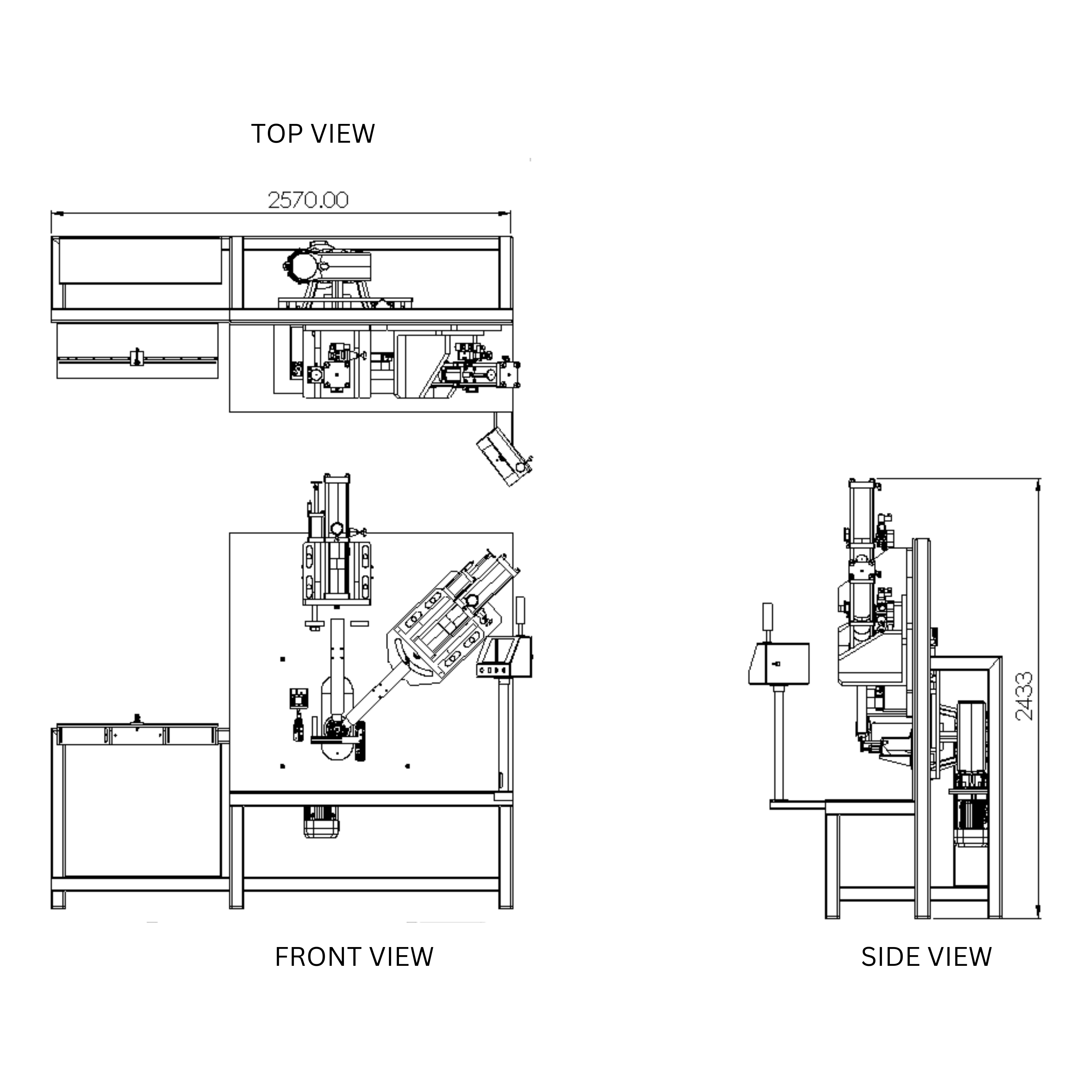

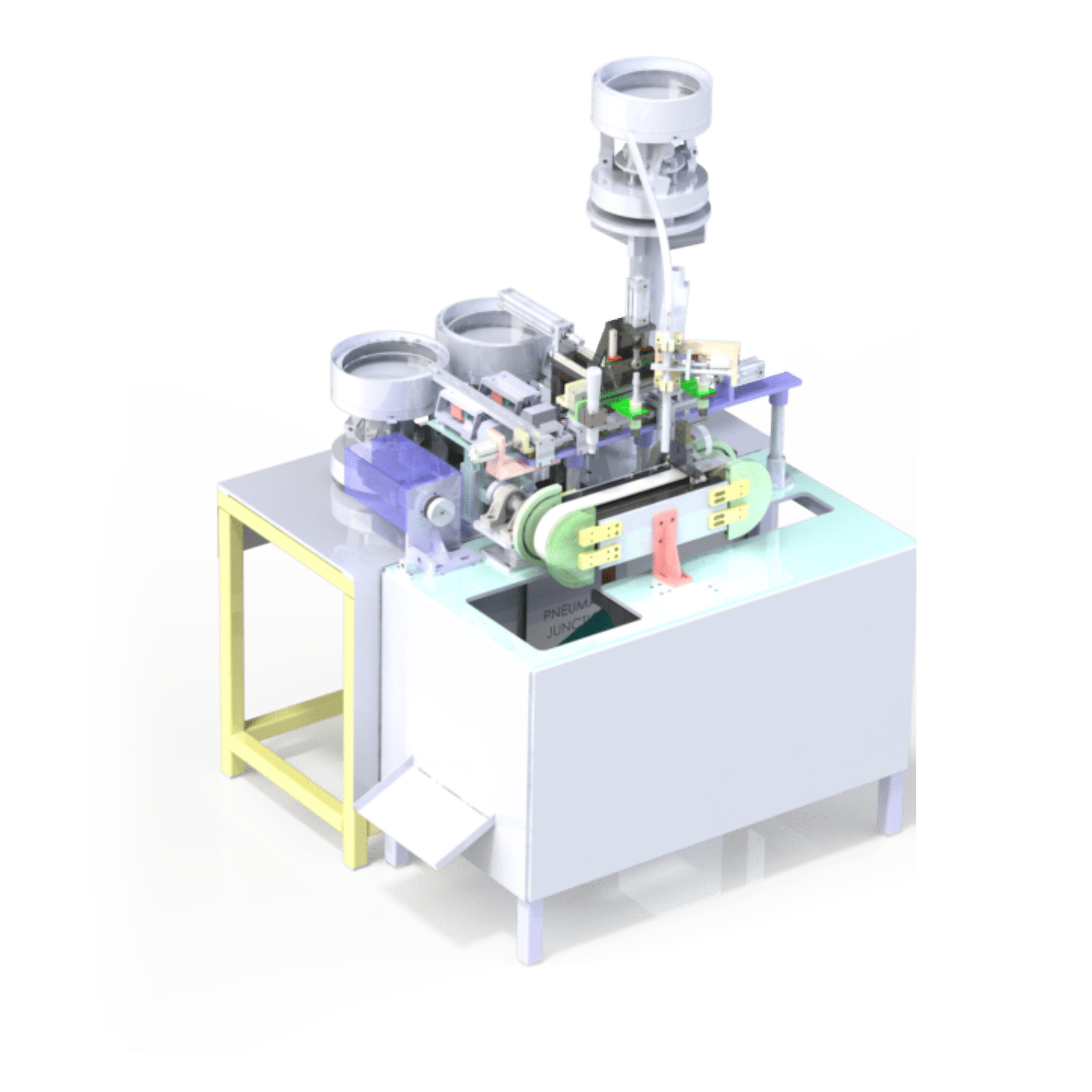

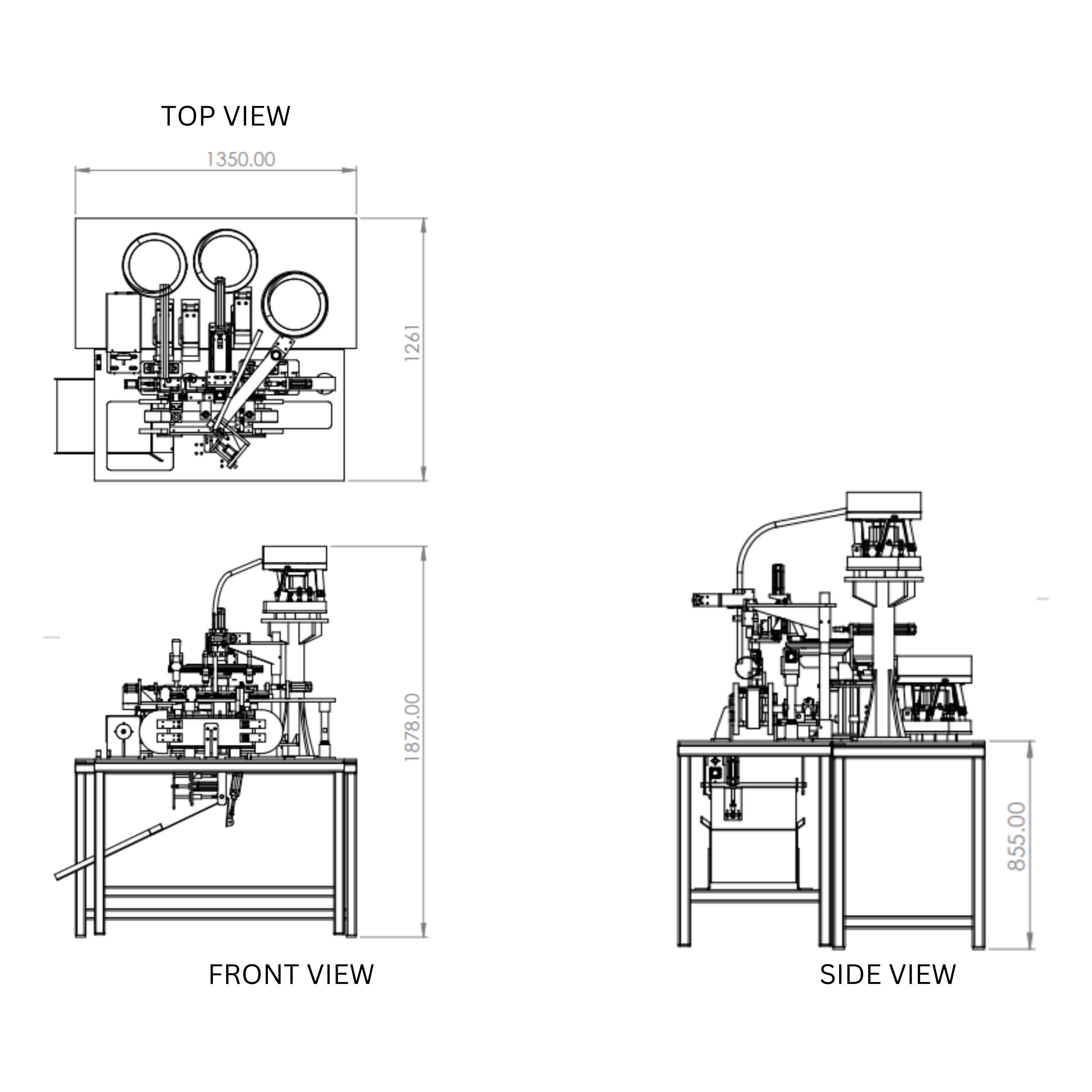

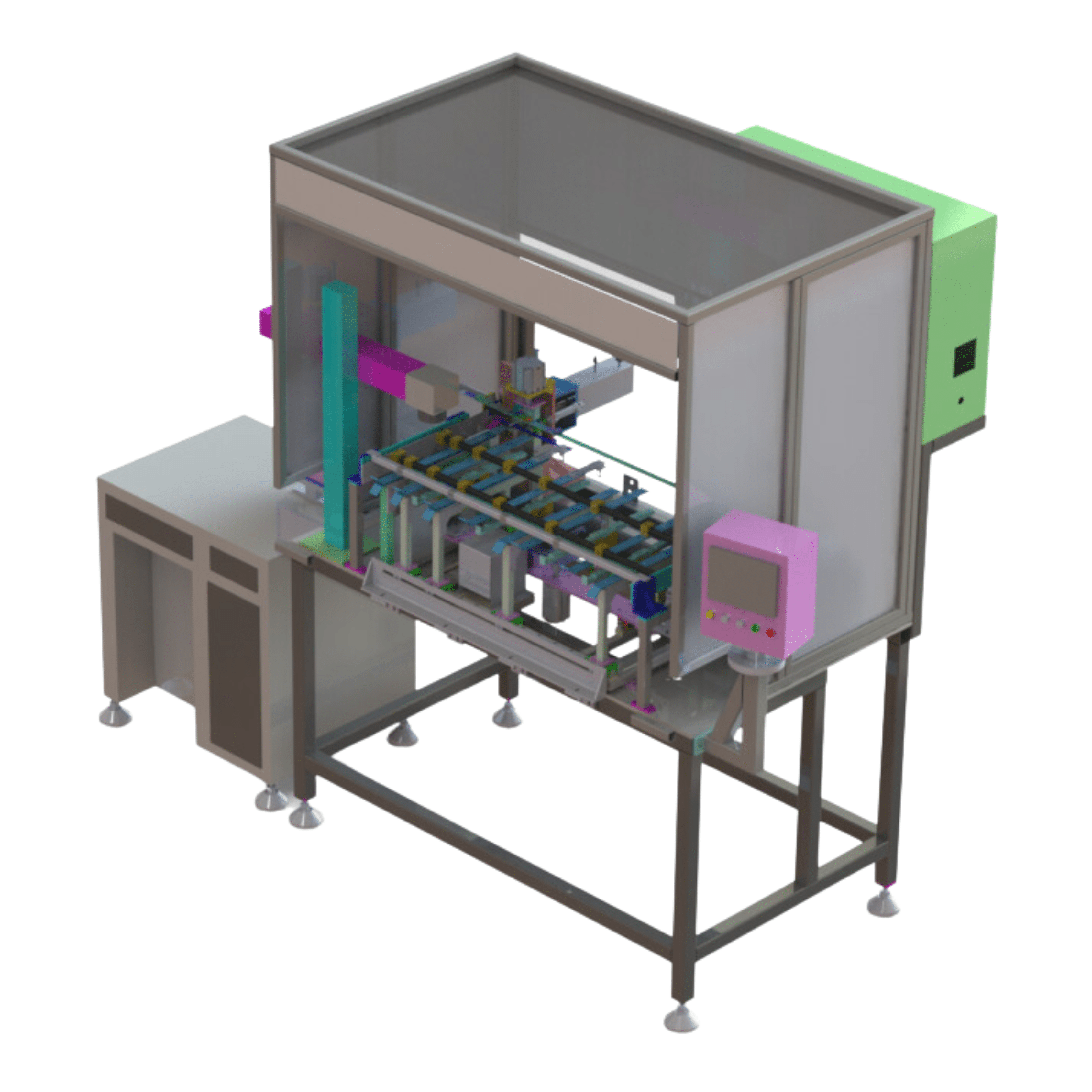

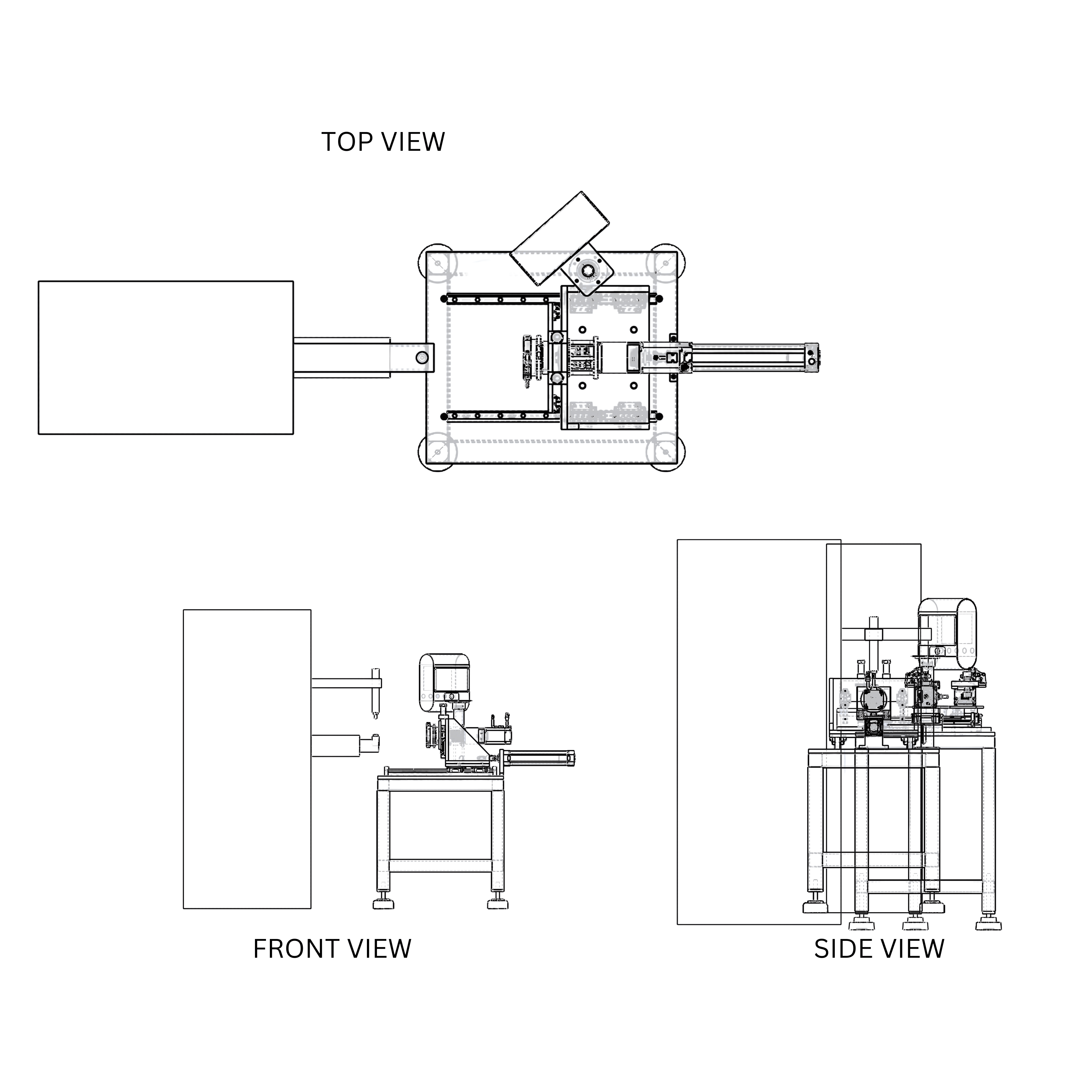

CLAMP ASSEMBLY AUTOMATION machine

Features

- Seamless integration of vibratory feeders, pick and place units, and automated crimping stations for streamlined assembly processes

- Precision handling ensures accurate placement of fasteners onto workpieces with spring clamps, maintaining consistent quality.

- Efficient operation with automated ejection mechanisms and high-speed functionality maximizes production output.

- Versatile adaptability to various assembly tasks and environments offers flexibility and scalability.

- Cost-effective solutions reduce labor costs, enhance quality control, and improve overall operational efficiency

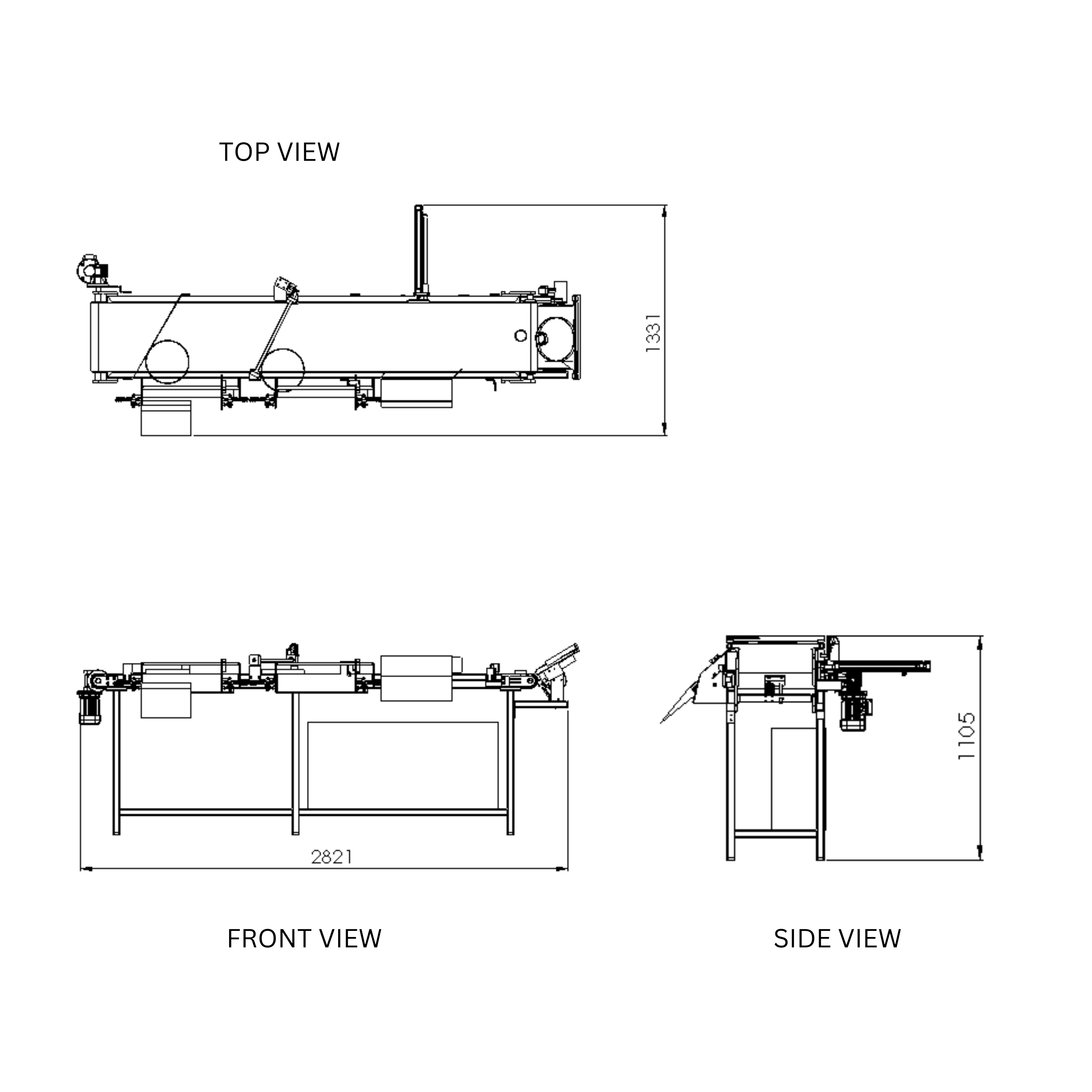

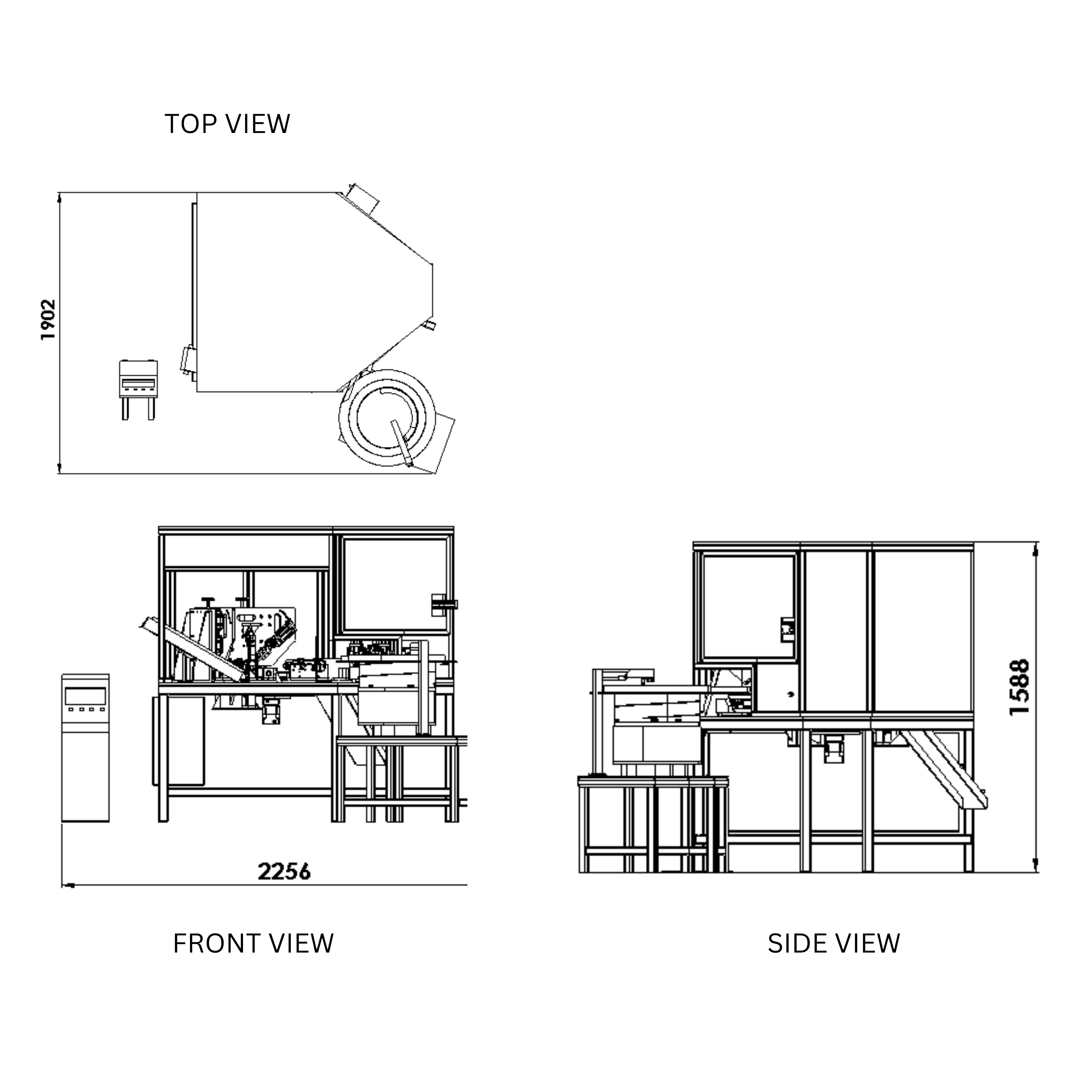

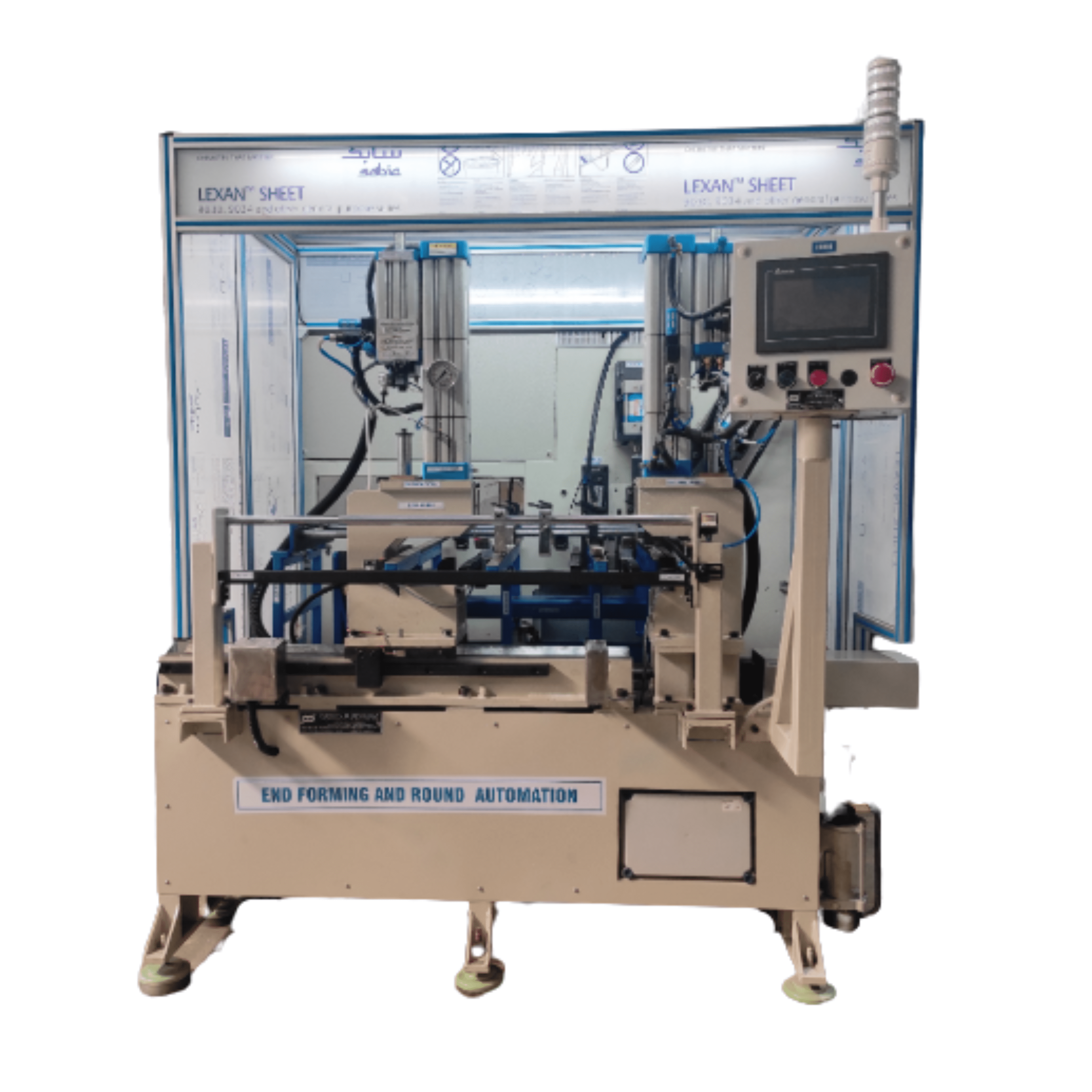

end forming & round automation

Features

- Adjustable walking beam for sliding of band to punching station to Rolling Station

- Hydro pneumatic cylinder for punching station in which right side is fixed which is t-nut side.

- Second punching station which sliding with help of lead screw mechanism according to length if band.

- Walking beam is used again for feeding to rolling station.

- With pneumatic cylinder & follower rolling if band is done.

- Adjustable die is done according to families with lead screw mechanism.

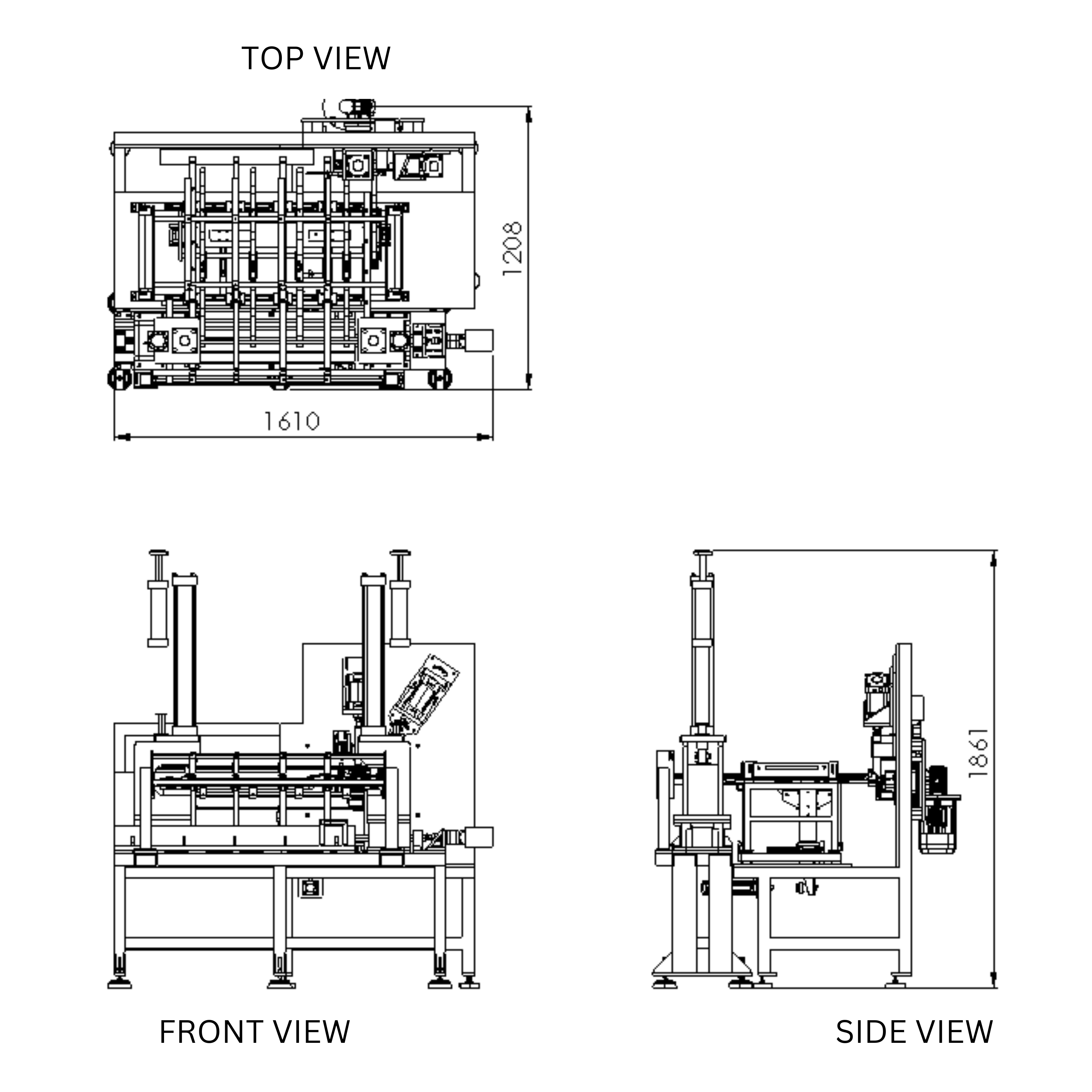

Multi Spot Welding Machine

Features

- Multi-location Spot Welding

- PLC Control

- Automation

- No Fixture Arrangement Changes

- Enhanced Productivity

- Cost Efficiency

- Ease of Operation

- Time Saving

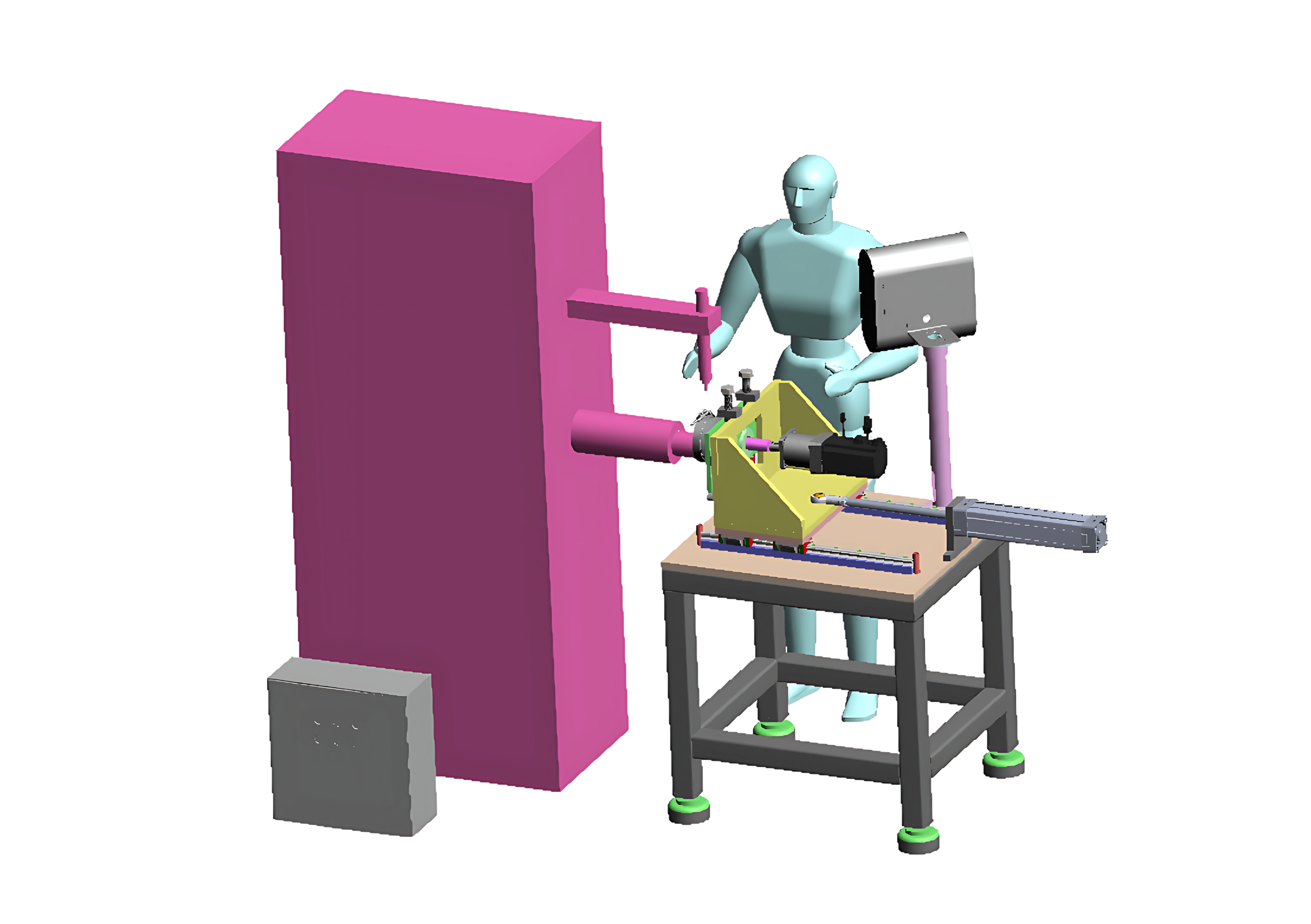

v bend welding machine

Features

- Specialized Fixtures: Customized fixtures tailored for V-bend spot welding ensure optimal performance and accuracy.

- Automation: Once the job is loaded correctly by a human operator, the machine operates autonomously, minimizing manual intervention.

- Time Efficiency: Enhances productivity by automating tasks

- Cost Effectiveness: Reduces labor costs and increases operational efficiency

- Increased Production Rate: Optimizes production throughput, meeting demanding production schedules effectively.