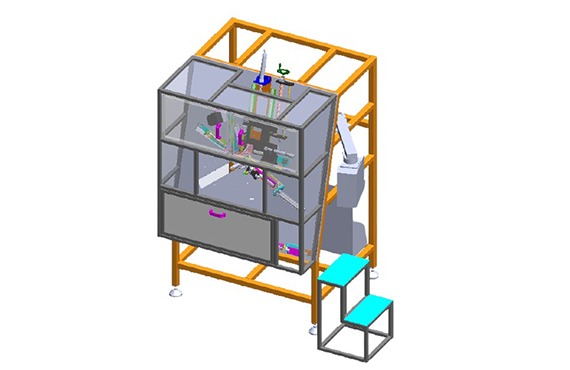

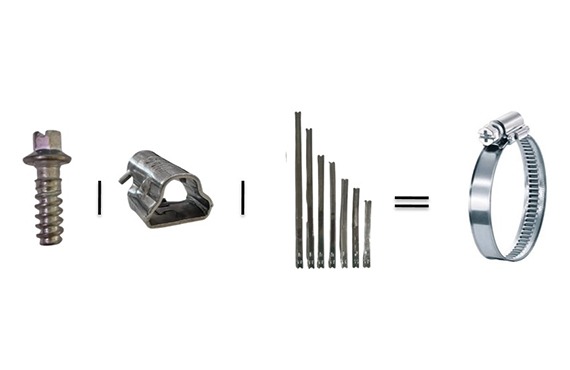

HOSE CLAMP AUTOMATION

HOSE CLAMP ASSEMBLY

- Automatic screw loading and screw tightening

- Hosing crimping

- 17 different size handled (min- Ø30 to max-Ø100)

- Easy changeover

- Precise Assembly

- Greasing Provision

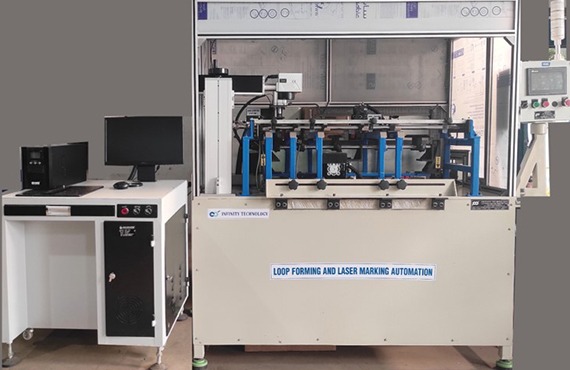

END LOOP FORMING AND LASER MARKING MACHINE

Features

- Manual loading & auto unloading by pneumatic actuators.

- Servo based slider mechanism for strip length adjustment.

- Motorised loop forming unit from both side.

- Pneumatic based strip holding unit.

- Servo based end length adjustment unit.

- Auto ejection by pneumatic system

- Safety canopy

- Working air pressure 5-6 bar.

- PLC base control panel used with HMI.

- Rigid structure robust structure.

- Cycle time:- 12-15 parts/min.

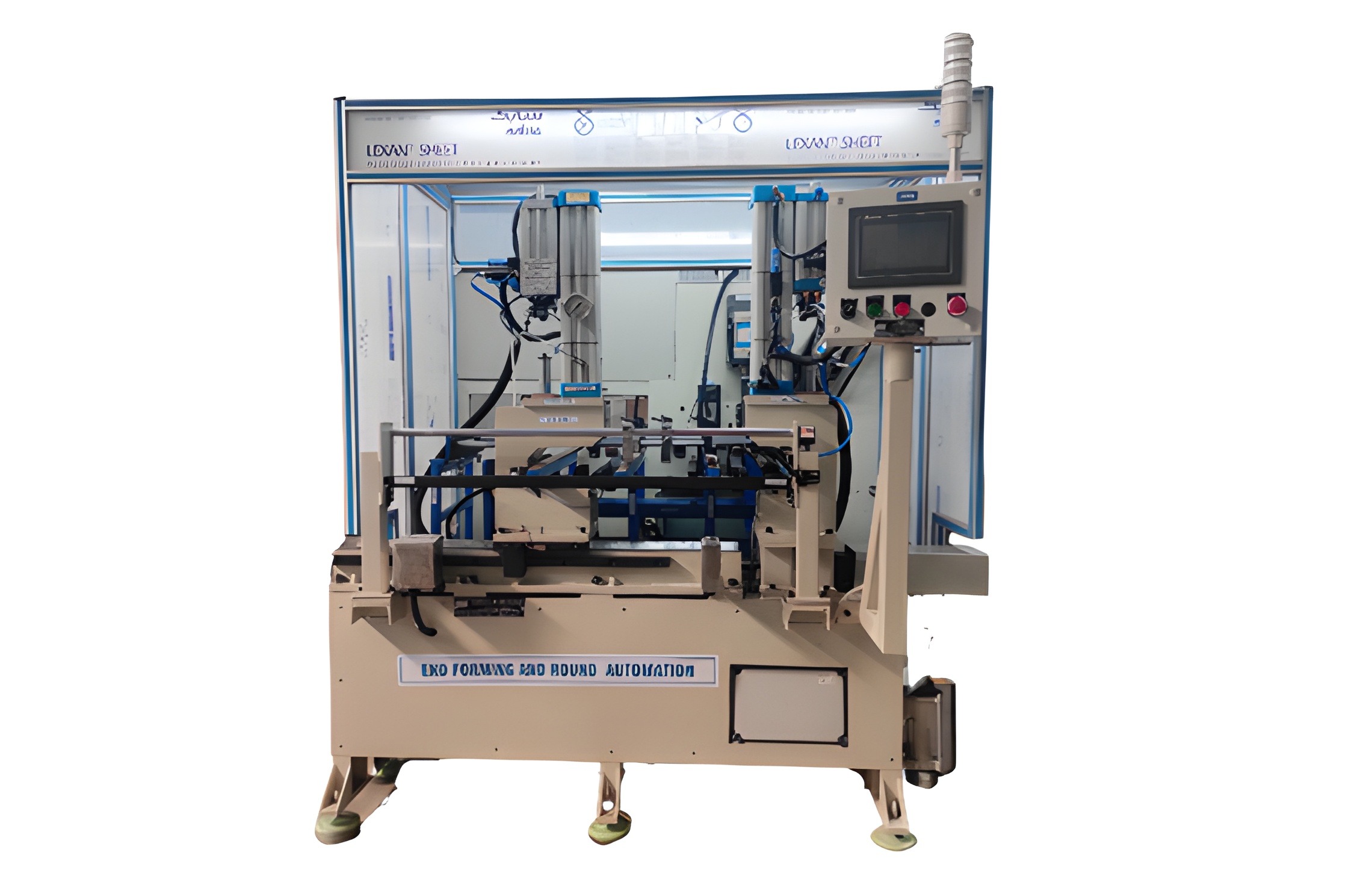

END BENDING AND ROLLING AUTOMATION

- Manual loading of band.

- Adjustable walking beam for sliding of band to punching station to Rolling Station

- Hydro pneumatic cylinder for punching station in which right side is fixed which is t-nut side.

- Second punching station which sliding with help of lead screw mechanism according to length if band.

- 4.8 tone force is applied for punching.

- Walking beam is used again for feeding to rolling station.

- With pneumatic cylinder & follower rolling if band is done.

- Adjustable die is done according to families with lead screw mechanism.

- PLC base control panel used with HIM.

- Rigid & robust structure.

- Cycle time :- 12-14parts per min.